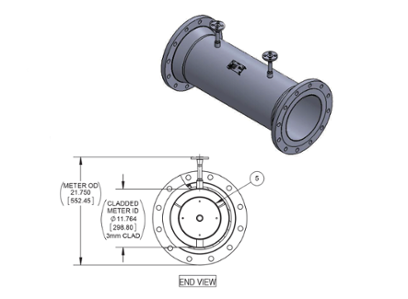

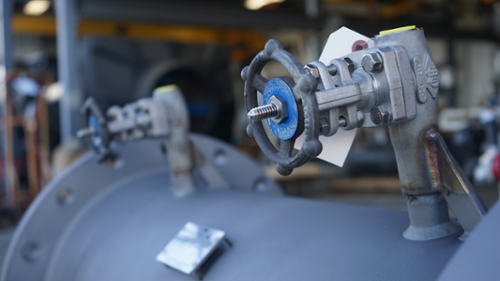

While there are many quality control procedures McCrometer performs to ensure a meter is manufactured to spec and in accordance with ISO 9001 (among other standards), there’s a specific test that some McCrometer customers opt to have performed on their meter. Known as...