V-Cone Material Construction: An Overview

The V-Cone® is one of McCrometer’s most versatile flow meters, in the ability to customize pressure taps, end connections, and most of all – material of construction.

Often, the material construction varies from customer to customer based on the demands of the application. Luckily, the V-Cone can meet the most demanding of applications!

So, what exotic materials are available for V-Cone construction? We spoke with the V-Cone engineers who quote custom V-Cones for our customers, and they provided an overview of the most popularly manufactured V-Cone materials.

The Common V-Cone Materials

The most common materials requested by V-Cone customers are different grades of stainless steel, like SS316, SS304, SS304L, S316L, and S316H depending upon the process application parameters like temperature and pressure.

Considering the project needs and application, stainless steel is preferred in different industrial verticals such as oil and petroleum refining, food processing equipment, pulp and paper processing, construction, chemicals and pharmaceuticals, and more. Stainless steel exhibits excellent corrosion resistance, higher creep, stress-to-rupture and tensile-strength at elevated temperatures and is able to maintain cleanliness.

Carbon steel, another popular material, is often the exclusive choice of pipeline designers, as it’s one of the most price-conscious materials.

For high-pressure applications, the V-Cone can be made in a high-tensile carbon steel in grades like X52, X60, and X65.

Low-temperature carbon steel (LTCS) is often a choice for V-Cone material construction in applications like water supply systems, food processing, and power plants. Based on the demands of the industry and application specifications, McCrometer also offers a carbon steel grade A105.

V-Cones Constructed of Alloy Materials

Subjective to project specifications and application, alloy materials are commonly used in oil and gas, energy, construction, and the automotive industries.

V-Cones are offered in different grades of chrome-moly (chromoly) like P1 and P11. Chromium-molybdenum alloy steel, commonly referred to as a chrome-moly, is a material that benefits applications with high pressures and a range of temperatures.

Duplex for V-Cone

The V-Cone is offered in Super Duplex, a material sometimes chosen for applications in petrochemical, water desalinization, chemical processing, and marine and shipping. A stainless material, Super Duplex is an alloy of austenite and ferrite offering robust strength and the added corrosion resistance from its high molybdenum and chromium content. This corrosion resistance makes Super Duplex able to withstand harsh flow media like seawater or astringent chemicals. Often, applications involving heat exchangers and offshore oil and gas platforms will opt for duplex stainless steel, similar to Super Duplex in its corrosion-resistance and strength properties.

Hastelloy for V-Cone

Popular for seawater applications, Hastelloy is another corrosion-resistant alloy that’s highly versatile and effective at reducing and mildly oxidizing corrosive fluids.

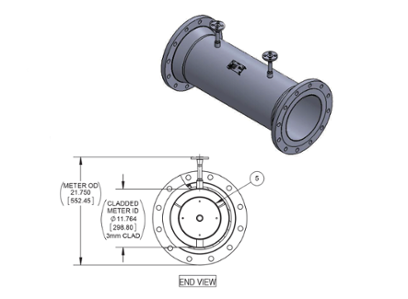

The above image shows a V-Cone manufactured for seawater and constructed of a carbon steel pipe and Hastelloy cone. Brilliant green in color, this meter is also a perfect example of another material construction option we offer for customization – color!

Inconel for V-Cone

Inconel 625 is another popular material for the V-Cone, offered in UNS designation N06625. It’s commonly used in applications requiring high strength, fracture toughness, fabricability, and resistance to corrosion. Inconel 625 is a nickel-based alloy that protects against corrosion and oxidation and is often used as a material for cladding. Learn more about our weld-overlay and cladding processes in our blog on the topic.

Inconel 825 is also offered, chosen for many oil and gas extraction applications due to high-temperature resistance and oxidation resistance. Many of these applications require a superalloy metal that can withstand volatile gasses and extreme environments.

The List Goes On

The above materials are only popular requests; McCrometer has manufactured V-Cones for customer projects requiring Monel and titanium and other exotic materials. Regardless of the material chosen for V-Cone manufacturing, all finished products are produced under a quality management system recognized by international standards, including ISO 9001.

The vast flow benefits and long lifespan of 25+ years make the V-Cone an exceptional investment meter; customizing the V-Cone’s material construction creates a tailor-made asset for your flow project. For additional information about the V-Cone, visit the product web page, or request a quote from our V-Cone Applications Engineering team.

Related Posts

Featured Posts

Choosing the Right Non-Contact Flow Meters: A Quick Dive into Radar and Laser Technologies

When measuring open channel flow wastewater and stormwater, non-contact flow technology is the ideal method, able to provide an accurate velocity and flow rate. Especially in the wet weather season, non-contact flow technology greatly benefits open channel...

Meeting BABA Compliance And Expanding Opportunities

Content Recorded and Published at WEFTEC in October 2024 In this episode of The Water Online Show: On Location, (now former) McCrometer President Pete Oveson dives into the company's story and recent developments shaping its future. He begins with an overview of...

McCrometer, Inc. Announces Redesign of FlowComTM Digital Register

FOR IMMEDIATE RELEASE: September 3rd, 2024Contact: Aimee Davis, Vertical Marketing Manager, Agriculture McCrometer, Inc.AimeeD@mccrometer.com Hemet, Calif. – McCrometer, Inc., a globally recognized flow meter manufacturer, today announced the launch of their...

Request More Information