V-Cone End Connections, Explained

Part of the V-Cone®’s appeal is its ability to be customized, including made-to-order end connections – a major benefit for engineers with a long list of specifications to meet and project goals to accomplish.

We spoke to the McCrometer V-Cone engineers about the various end connections available, and they shared answers to some of the most frequent customer questions.

What V-Cone End Connections are Best for High-Pressure Applications?

The V-Cone is commonly sold into high-pressure applications, as the meter’s ability to withstand up to 15,000 PSI and tolerate harsh media like liquid natural gasses and even wet gas make it an ideal metering solution.

For extremely high-pressure applications, American Petroleum Institute (API) flanges are often required by the customers. However, McCrometer isn’t limited to these hub end connections, and can accommodate numerous customer specifications. API end connections suit applications for crude oil and enhanced oil recovery, among others. For meters containing class 600 flanges or above, a weld-neck end connection is recommended, as it’s a more durable connection suiting high-pressure applications. Additionally, if the customer specifies a Weldolet®, a common pressure tap requested on V-Cones, the end connection would be weld-neck, to meet the specifications of the Weldolet taps.

What End Connections are Most Common for the V-Cone?

Depending on factors such as size and weight class, there are some standard end connections recommended by the McCrometer V-Cone engineers.

A popular standard end connection is the slip-on, which is similar to the weld-neck option, but usually at a lower cost, ideal for non-compressible fluids. A slip-on end connection overlaps a pipe, and a weld-neck seam is flush; a slip-on connection offers a smaller overall footprint, which may be highly desirable for customers looking to reduce space and weight.

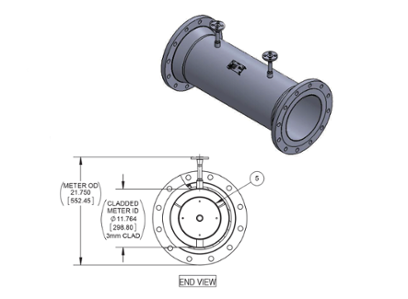

A V-Cone with a raised face slip-on flange end connection.

For higher-pressure applications specifically at a larger line size, compact flanges are often specified for the meter, as they use much less material for construction, thus reducing the overall meter weight and price tag. This type of end connection allows V-Cone customers in applications such as offshore platforms meet their weight and space requirements.

What Other End Connections Exist?

For customers requiring a shorter lead time, or if they’d prefer to weld on their own flanges, a beveled end connection is ideal. This particular end connection may also be preferred by customers who have requested their meter be constructed of exotic materials. If a platinum or nickel alloy V-Cone is ordered, the customer may want to save on budget and weld the meter right into their line. The V-Cone offers a 25+ year lifespan and virtually no maintenance needed during that time, giving customers confidence when welding a beveled end V-Cone directly into the pipeline.

Smaller V-Cones, typically less than or equal to 4” nominal pipe size, may use a threaded end connection, which is a national pipe thread (NPT) used for connecting the V-Cone meter to the mating pipeline, typically for lower pressure or liquid media applications.

For flanged V-Cones, the ring type joint (RTJ) is prevalent in many metering projects. This acronym refers to the groove on the face of the flange that accommodates certain gaskets customary in higher-pressure applications.

Alternately, both raised face and flat face flanges are available as well, both commonly requested for process plant applications, as these flanges are specified to compliment the gaskets used during the installation process.

McCrometer customers often require standard flanges per the American Society of Mechanical Engineers (ASME) and the American National Standards Institute (ANSI), both of which McCrometer can meet.

Deutsches Institut für Normung (DIN) flanges, a common standard end connection for the European Union and in Australia, are regularly requested during international orders. McCrometer has the ability to meet a myriad of performance and product standards, more of which are detailed in our blog on meeting and exceeding flow meter standards.

What End Connection is the Best Option for my V-Cone?

The best end connection for your V-Cone is the one that allows you to best achieve your flow project goals. Whether you’re finding a custom solution for a tough retrofit project, or consciously staying beneath specific weight and space restrictions, the McCrometer V-Cone engineers can assist you by providing information on all the end connections available.

To get started on your V-Cone flow project, request a quote or contact the factory for more information.

Related Posts

Featured Posts

Choosing the Right Non-Contact Flow Meters: A Quick Dive into Radar and Laser Technologies

When measuring open channel flow wastewater and stormwater, non-contact flow technology is the ideal method, able to provide an accurate velocity and flow rate. Especially in the wet weather season, non-contact flow technology greatly benefits open channel...

Meeting BABA Compliance And Expanding Opportunities

Content Recorded and Published at WEFTEC in October 2024 In this episode of The Water Online Show: On Location, (now former) McCrometer President Pete Oveson dives into the company's story and recent developments shaping its future. He begins with an overview of...

McCrometer, Inc. Announces Redesign of FlowComTM Digital Register

FOR IMMEDIATE RELEASE: September 3rd, 2024Contact: Aimee Davis, Vertical Marketing Manager, Agriculture McCrometer, Inc.AimeeD@mccrometer.com Hemet, Calif. – McCrometer, Inc., a globally recognized flow meter manufacturer, today announced the launch of their...

Request More Information