Stacking Transmitters: Getting the Most Out of Your V-Cone

While it’s true that the V-Cone® primary element does the flow measuring, the transmitter is also an important component to effective flow measurement, and the decision-making that results from that data collection.

For high turndown applications, customers have the option to stack transmitters. So, what does stacking transmitters mean for your pipeline, and what kind of benefits will it bring to your flow project?

Let’s review.

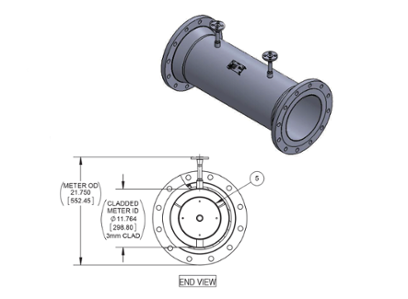

Calibrating a V-Cone with stacked transmitters at a NIST-traceable flow lab.

What Does Stacking Transmitters Mean?

Stacking differential pressure (DP) transmitters is the process of utilizing two flow meter transmitters to cover a DP range larger than what can accurately be measured by a single DP transmitter. This is accomplished by spreading the DP measurement across two DP transmitters. A high range DP senses the upper DP measurement and a low range DP senses the lower DP. As the flow drops to the bottom end of accurate measurability of the high range, the DP the system switches the measurement over to the low range DP. This is known as ‘dual’ or ‘stacked DPs.’

Achieving Accuracy by Stacking Transmitters

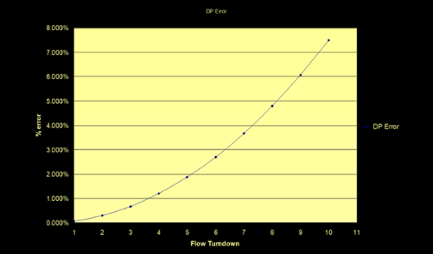

As a rule of thumb, our V-Cone engineers suggest stacking transmitters anytime your turndown ratio is higher than 10:1. If you’re investing in a V-Cone, you’re looking to achieve up to ± 0.5% accuracy; in a 10:1 flow turndown, the DP is from 1” to 100”. The typical V-Cone transmitter accuracy is .075% of the span, meaning that a 100” span has a ± 0.075”. If you have 1% error in a component, such as a 1% error in DP, it results in 0.5% error in flow rate.

A graph showing the DP error increasing as the flow turndown increases.

When you stack transmitters, you minimize the low-end error. You can maintain that ± 0.5% accuracy through stacking transmitters and creating a higher than 10:1 turndown. Ultimately, by stacking transmitters, you’re improving the accuracy for high turndown applications.

Common Transmitter Misconceptions

One of the frequent misunderstandings about transmitters is the fact that the transmitter turndown is different than the V-Cone turndown. A transmitter is the upper range of the flow rate divided by the span; flow meter turndown is maximum flow divided by minimum flow. This is the actual range you’re measuring.

Most transmitters have a transmitter turndown of 10:1, so, if you span a transmitter more than the anticipated differential pressure range the accuracy is going to worsen. This particular affect on accuracy is the reason McCrometer engineers specify certain transmitters based on specific applications to accommodate for various flow ranges.

Popular Applications for Stacking Transmitters

The McCrometer engineers often encounter customers with steam applications choosing to stack transmitters because of varying flow rates during different seasons; steam for heating is in higher demand during the winter months. More recently, there’s a trend of universities investing in stacking transmitters for their steam applications, although it’s likely that many systems engineers and operators aren’t aware that the accuracy of their transmitters isn’t ideal at the low end of their turndown.

A McCrometer customer had a steam application that required a turndown of 20:1 for both forward and reverse flow. Due to this high turndown requirement, if a transmitter of 200” was installed, the accuracy of that transmitter would state incorrect values when flow began to reach the lower end of the flow range.

For example, should that application reach a max flow of 10,000 lb/h with the DP around 77”WC (water column), when the flow is lower at about 6000lb/h or less the DP would be less than 30”WC causing the 200” transmitter to call out inaccuracy in DP.

By stacking transmitters and meeting that turndown requirement of 20:1, the transmitters could calculate the meter DP for the lower end flows and provide a more accurate reading. Ultimately, stacking transmitters allowed this campus steam customer to achieve their flow project goals and get the data necessary for daily operations.

Advice for Stacking Transmitters

When planning out your flow project, ensure you’re specifying an achievable flow rate for your flow project. Predicting your flow range is critical; if a flow meter is designed for a velocity twice the actual amount, the V-Cone will operate at the bottom end of the flow rate it was designed for.

Achieving your flow measurement goals is of utmost importance to us, and our engineering experts are available to consult you on your metering project and provide you with the information you need to make decisions for your project.

We recommend visiting the V-Cone product family page for more specs on our DP meter, and when you’re ready to get started, feel free to request a quote.

Related Posts

Featured Posts

Small Package, Big Impact: The Importance of Desiccant Cartridge Maintenance

You’ve likely seen a desiccant cartridge, in the form of the small silica gel packet accompanying food products, or the activated carbon packet at the top of pharmaceutical bottles. It’s also commonly used in electronics and near sensors, especially for...

Choosing the Right Non-Contact Flow Meters: A Quick Dive into Radar and Laser Technologies

When measuring open channel flow wastewater and stormwater, non-contact flow technology is the ideal method, able to provide an accurate velocity and flow rate. Especially in the wet weather season, non-contact flow technology greatly benefits open channel...

Meeting BABA Compliance and Expanding Opportunities

Content Recorded and Published at WEFTEC in October 2024 In this episode of The Water Online Show: On Location, (now former) McCrometer President Pete Oveson dives into the company's story and recent developments shaping its future. He begins with an overview of...

Request More Information