V-Cone® for Enhanced Oil Recovery (EOR): Gas Lift Applications

On the production end of the oil and gas industry, gas lift techniques are often used to draw oil to the surface in enhanced oil recovery processes. The gas lift may be intermittent or continuous, and involves high-pressure gas being pumped into wells to stimulate highly viscous oil. Operators monitoring gas lift rates in a variety of wells can rely on the V-Cone for accurate flow measurement and rugged design requiring minimal-to-no maintenance.

Let’s review.

Complex Oil and Gas Applications

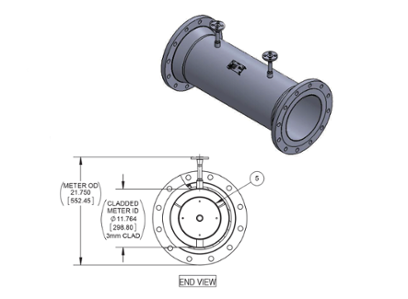

The V-Cone is a flow meter implemented into a wide variety of flow applications, many of them hazardous, complex, and with a variety of challenges to overcome. Gas lift, a popular V-Cone application, requires corrosion-resistant equipment able to withstand harsh flow media. The V-Cone can be manufactured from a variety of common and exotic materials, including 304L stainless steel, and may even be cladded should customer specifications require it. Additionally, if specifications require an expensive material, the V-Cone’s straight-run requirements are advantageous. Requiring minimal to zero straight run, the V-Cone saves on additional (possibly expensive) piping costs and installation space due to its self-conditioning design.

Gas lift processes aim for accuracy, as too much or too little gas injected into the well casing can result in inefficient production. Offering up to ± 0.5% accuracy, the V-Cone and its accompanying transmitter provide operators and engineers with the accuracy and repeatability they need to make timely, informed decisions about their gas lift operations.

Varying well casing pressures as gas injection valves open and shut during gas lift operations require a V-Cone that can cover that high turndown. With stacked transmitters, the V-Cone can measure a 20:1 turndown with low permanent pressure loss, lending efficiency to the overall operation. Metering benefits like this can greatly impact an oil and gas company’s bottom line, preventing energy loss and eliminating the need for additional gas compression.

Flow Meter Options for Gas Lift

As with numerous oil and gas flow applications, the orifice plate is often chosen based on its price point and “off-the-shelf” convenience, offering low lead times and familiarity for many engineers working on flow projects. While the orifice plate may be a household name for oil and gas projects, the average lifespan is minimal in corrosive, harsh environments. This can halt pipeline operations for maintenance or meter replacement when the orifice plate’s edges dull or corrode over time. Additionally, the orifice plate can be prone to permanent pressure loss, and accuracy is often affected by differences in flow density, pressure, and erosion. Significant straight-run requirements can also affect overall project cost and footprint, especially in retrofit applications.

The Venturi meter has a high-pressure recovery compared to the orifice plate and is often more accurate. However, the Venturi’s sheer size alone can be a deterrent, especially in offshore operations where space and weight are a concern.

Vortex flow meters are another choice for gas lift, as they’re economically priced and have a lower pressure drop than the orifice plate. However, they are easily affected by surrounding vibrational resonance, have a low-flow cutoff, and require straight-run of 15:5 or higher in some cases.

The V-Cone’s primary element is self-conditioning and can be extremely corrosion-resistant based on the material of construction. The structure of the V-Cone, including the vertical and horizontal supports, is built to withstand external vibration. The V-Cone, while not as universally familiar to engineers and operators as the orifice plate, is still a straightforward and transparent piece of equipment. Operators don’t need any formal expertise to validate the transmitters, which are tied to a flow computer. The V-Cone system doesn’t require any proprietary software, and is easy to verify, isolate the components, and complete easy installation with minimal-to-zero maintenance. The V-Cone’s 25+ year lifespan means less downtime, more peace of mind, and reliable flow data needed to ensure the gas lift is generating optimal flow production.

A V-Cone Retrofit Project

In early 2004, an FPSO customer contacted McCrometer regarding a gas lift flow measurement issue. Their existing 3” vortex flow meter was presenting a noisy flow signal and vibration at the installation point on the turret was the suspected cause. The customer was familiar with the V-Cone’s data with regards to signal stability and asked for a formal opinion of the current flow project. After a detailed review, including analysis of the proposed installation point on the turret model, McCrometer concluded the V-Cone would be a fitting solution. The V-Cone proved to be such a success in an application containing considerable vibrational resonance that the customer continued to implement V-Cones on additional oil and gas projects.

A V-Cone installed successfully on the customer’s FPSO.

A Key Advantage for Gas Lift

For customers desiring a flow meter to cover a wider range than 20:1 turndown with stacked transmitters, McCrometer provides the compact but mighty Wafer-Cone® flow meter. Ideal for small line sizes of 1” – 6”, the Wafer-Cone uses the same proprietary design principles as the V-Cone, with one major beneficial difference – an interchangeable cone. This “fast change replacement meter” is ideal for gas lift applications wanting to change their beta ratio for different flow conditions. The Wafer-Cone can measure from the day that enhanced oil recovery begins, until the day the well dries up! The flangeless design and interchangeable cone also contribute to a small project footprint and is an ideal solution for gas lift retrofit applications and offshore projects.

Tough Applications, Tougher V-Cone

Gas lift processes are complex enough. The metering choice is simple; the V-Cone is an investment flow meter that brings unprecedented value to enhanced oil recovery projects. The customization available is truly what makes this flow meter so applicable to varying processes, from the material construction, to the stacked transmitters, and even end-connections. To explore all of our customization options for our differential pressure product suite, check out our product page or contact the V-Cone Applications Engineering team at vconerfq@mccrometer.com

Related Posts

Featured Posts

3 Reasons Why Budget-Focused Farmers Invest in Integrated Telemetry

Allocating budget to flow technology may seem unjustifiable when funds are tight; flow meters and their electronics may already be installed, giving no reason to replace or add additional units when the current solution is in fine working condition. However, flow...

Small Package, Big Impact: The Importance of Desiccant Cartridge Maintenance

You’ve likely seen a desiccant cartridge, in the form of the small silica gel packet accompanying food products, or the activated carbon packet at the top of pharmaceutical bottles. It’s also commonly used in electronics and near sensors, especially for...

Meeting BABA Compliance and Expanding Opportunities

Content Recorded and Published at WEFTEC in October 2024 In this episode of The Water Online Show: On Location, (now former) McCrometer President Pete Oveson dives into the company's story and recent developments shaping its future. He begins with an overview of...

Request More Information