Electromagnetic Flow Meters, Flow Straighteners, and Vanes: Compatible or Not?

Those familiar with propeller flow meters are usually familiar with their common counterparts, flow straighteners and vanes. Implemented to reduce swirl in shorter straight-run applications, straighteners are a complementary instrument for agriculture, irrigation, and municipal flow measurement applications.

So, if flow straighteners and vanes bring so much benefit to propeller-using applications, is the same true for electromagnetic (mag) measurement applications? We spoke with the McCrometer engineering team and got the answer.

Different Measurement Technology and the Flow Straightener

A propeller meter measures flow in volumetric terms: the amount of water flowing through the pipe rotates the propeller so many times. Nearby elbows, T-junctions, and active valves can cause swirl in the line, which will then affect the propeller to rotate faster or slower, affecting the reading. A flow straightener, like McCrometer’s FS100 and FS200, or straightening vanes such as the bolt-in hex and tri vanes, remove swirl and irregular flow profiles in order to allow the propeller meter to gain an accurate volumetric reading.

The FS200 (left) and FS100 (right and back) Flow Straighteners displayed at a trade show.

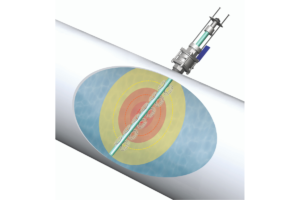

Insertion mag meters require a fully developed flow profile in order to read the flow rate. A full flow profile is the flow gradient across the pipe section; if you take a look at a cross-section of the pipe, the friction between the fluid and the pipe causes the flow to be fastest in the center of the pipe and slower near the pipe walls. Since mag meters measure velocity by assessing a fully developed flow profile, implementing a flow straightener would interfere with the mag meter’s accuracy, as it removes the flow profile and creates a more homogeneous velocity.

The FPI Mag measures across the full flow profile to achieve its accuracy reading.

McCrometer’s Mag Meters

Flow straighteners and vanes can affect mag meters differently based on their design. The FPI Mag®, SPI Mag®, and Mc®Mag3000 flow meters are most accurate on a fully developed flow profile, as their electrode placement and sensor structure require some distance from flow disturbers. For full-bore mag meters such as the Dura Mag® and the Ultra Mag®, they’re less impacted by straightening components due to their full bore design, but it’s still completely unnecessary to implement a flow straightener or vanes for a meter already achieving a ± 0.5% accuracy with 1 diameter upstream and 0 diameter downstream straight-run requirements.

Existing Flow Straighteners in the Line

For most applications, the recommendation is to remove existing flow straighteners and vanes from the pipeline prior to installing a mag meter. However, sometimes that can be considered a hassle in terms of time investment or manpower, due to the shift in straight-run requirements.

McCrometer’s newly launched McMag2000™ is a little more flexible in tolerating existing straightening components in the line. The Mc®Mag 2000’s sensor measures the center velocity of the flow and uses averages to achieve its ± 2% accuracy. This measurement tactic is built into the calibration. McCrometer’s engineers have tested many Mc®Mag 2000 flow meters across diameter size range and included flow straighteners in that testing to assess change in velocity and reading. This extensive testing allowed the engineers to manipulate calibration variables in order to account for flow straighteners and vanes. So, for customers who have an existing straightening component, in many cases a retrofit project, we can accommodate that by utilizing our proprietary calibration tool and programming that variable into the Mc®Mag 2000’s converter.

The use of a mag meter with a flow straightener or vanes is a highly unique caveat to the normal electromagnetic technology; this condition was a goal for our engineers, as the Mc®Mag 2000 was meant for new installations as well as propeller retrofits. The ability to accommodate an existing flow straightening component ensures that the Mc®Mag 2000 is simple and easy to retrofit an existing Mc®Propeller without modifying the existing pipeline setup. Use of the Mc®Mag 2000 alongside straightening vanes or the FS100 or FS200 Flow Straighteners allows the meter to be applied to a wider range of applications, cutting the straight-run requirements in half.

Understanding the Technology

To make the most of your flow meter investment, it’s important to share as much information as possible about your flow project with the McCrometer team. There are many factors that will influence what kind of meter our team will recommend; understanding the surrounding environment, any potential pipeline interferences, and what the customer’s project goals are will help immensely. By understanding how the flow meter will interact with the customer’s existing setup, the flow meter can truly be utilized as a tool to make informed decisions about flow.

For more information about McCrometer’s mag meters, visit the mag product suite page on our website, or contact us for a quote on your next flow project.

Related Posts

Featured Posts

Choosing the Right Non-Contact Flow Meters: A Quick Dive into Radar and Laser Technologies

When measuring open channel flow wastewater and stormwater, non-contact flow technology is the ideal method, able to provide an accurate velocity and flow rate. Especially in the wet weather season, non-contact flow technology greatly benefits open channel...

Meeting BABA Compliance And Expanding Opportunities

Content Recorded and Published at WEFTEC in October 2024 In this episode of The Water Online Show: On Location, (now former) McCrometer President Pete Oveson dives into the company's story and recent developments shaping its future. He begins with an overview of...

McCrometer, Inc. Announces Redesign of FlowComTM Digital Register

FOR IMMEDIATE RELEASE: September 3rd, 2024Contact: Aimee Davis, Vertical Marketing Manager, Agriculture McCrometer, Inc.AimeeD@mccrometer.com Hemet, Calif. – McCrometer, Inc., a globally recognized flow meter manufacturer, today announced the launch of their...

Request More Information