Why Do We Measure? 10 Tips to Gain Buy-In to Meter with McCrometer

1. Know Your “why”

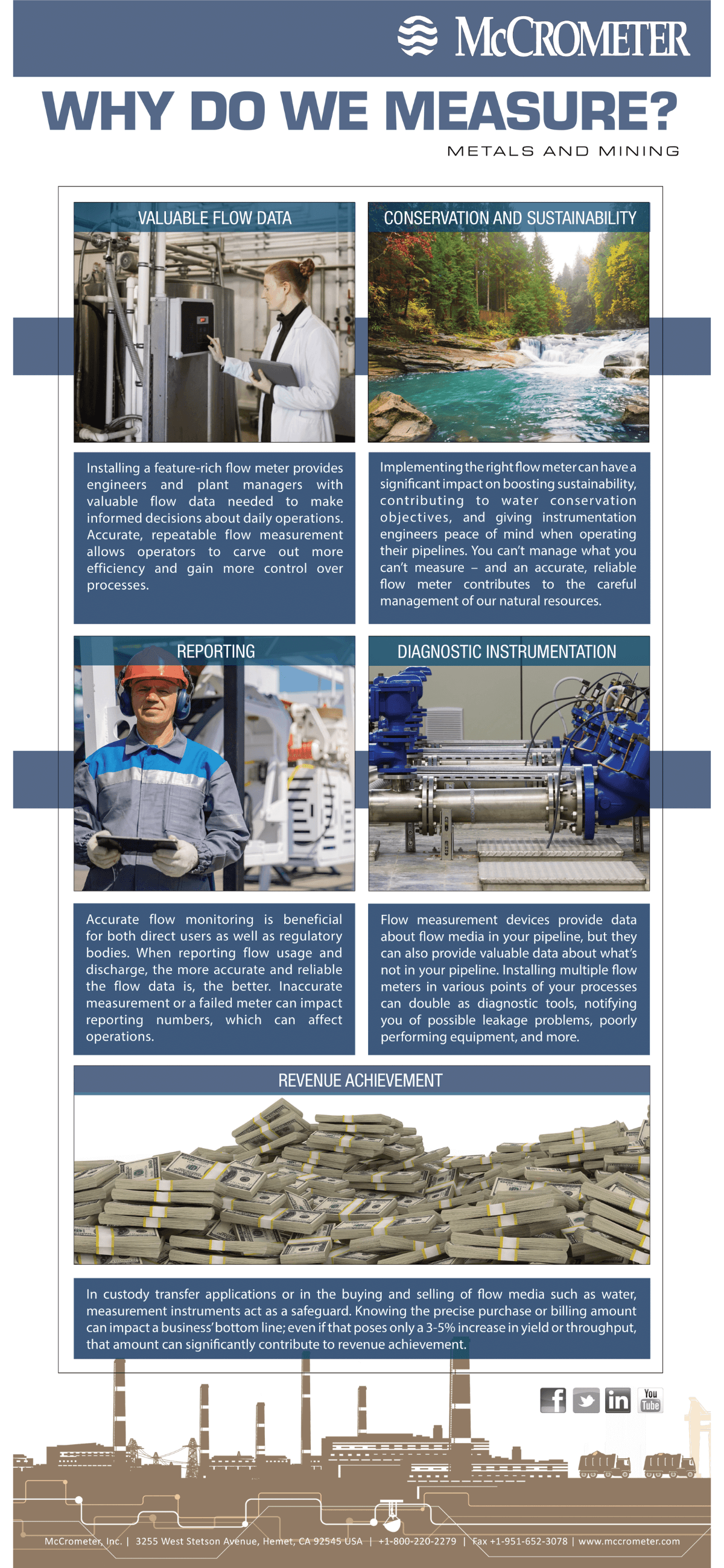

Understanding the purpose of the flow meter in your flow project and why you’re measuring is a great start when building your business case. Implementing a flow meter, especially a feature-rich flow meter, will provide you with valuable data. Are you controlling off the measurement point? Is this for a safety shutdown? Are you measuring to quantify a sale or purchase? Will this measurement be reported to regulating agencies? Understanding project goals and how a flow meter can contribute to your success will help you define the value of the flow meter, as well as the value of its features.

2. Identify the challenges of your application

Your flow application will have unique challenges and specifications that help determine the appropriate measurement technologies. If you’re confronted with insufficient straight pipeline and cannot compromise on accuracy, you can make your case for a McCrometer meter that performs with minimal-to-no straight run, such as the V-Cone® or FPI Mag®. If you’re dealing with a highly corrosive flow media in a tailings application, for instance, you can ensure your meter will handle abrasive solids by implementing the Ultra Mag®. Overall, understanding the application pitfalls to measurement will allow you to choose a flow meter that will perform adequately.

3. Quantify the impact of poor measurement

Oftentimes, there are consequences to poor flow measurement. For instance, if a line isn’t flowing enough water and the meter isn’t reporting that low flow, nearby equipment can be damaged. Additionally, inaccurate measurement or a failed meter can impact reporting to regulatory bodies like municipalities or the EPA. Inaccurate readings can also influence your bottom line, in cases such as custody transfer or the billing of drinking water. By quantifying the impact of poor performance, and even identifying the potential revenue achievement, you can gain buy-in to implement an accurate McCrometer flow meter.

4. Weigh the economical choice vs. an investment

When gaining buy-in from stakeholders, choosing the “cheaper chicken” doesn’t necessarily equate to the best economical choice. While initial purchase price is an important consideration, the life expectancy of the meter, durability, and ongoing maintenance should be factored into the overall decision. Oftentimes, investing in a more expensive, rugged flow meter will be less expensive in the long run compared to a cheaper meter you’ll have to spend time and money maintaining – or possibly replacing.

5. Consider the accuracy and repeatability

The return on your meter investment is a big deal! When you can bill for a more accurate water usage, carve out more efficiency in your processes, or obtain more control over your pipeline, it’s usually due to the accurate and repeatable measurement data your flow meter provides. The ROI from an accurate meter can be quantified and used to leverage support from stakeholders.

6. Focus on managing flow for efficiency

Implementing the right feature-rich flow meter can have a significant impact on boosting plant sustainability, contributing to water conservation objectives, and giving you peace of mind when abiding by regulatory requirements. You can’t quantify and manage what you can’t measure. You can gain tighter control of your flow, and even if that poses only a 3-5% increase in yield or through-put, that amount can justify the meter investment itself in a very short period of time.

7. Factor in a comprehensive flow measurement manufacturer

McCrometer has a full suite of products in propeller, differential pressure, and electromagnetic technologies. Our products range in size, material construction, and customization and can tolerate a variety of flow media, temperatures, viscosities, and more. Working with a manufacturer that offers such variety and customization ensures that you and your team have the right solution when you need it.

8. Emphasize the “set it and forget it” quality

McCrometer products are hassle-free, easy to install, require minimal-to-no maintenance, and boast a long lifespan. The V-Cone provides accurate measurement for 25+ years and the FPI Mag saves customers up to 45% on installation and total cost of ownership due to its hot-tap capabilities and maintenance-free design. These conveniences are a major benefit to engineers and plant managers, making it easy to gain their support.

9. Highlight short lead times and “Made in the USA”

McCrometer’s meters are manufactured in the Hemet, California factory by highly skilled welders and assemblers. The short lead times are due to the factory’s lean manufacturing practices, inventory management system, and prioritization of American-sourced raw materials. Every one of our mag meters is wet-calibrated in our on-site, NIST-traceable flow lab and all meters have proven field-use. Other manufacturers and meters may be preferred by your stakeholders due to historical use, but when your existing flow meter breaks, you need a replacement meter quickly. McCrometer can deliver, and that’s a substantial selling point to get your team on board.

10. Reiterate local support

When you call McCrometer technical support, you receive USA-based expertise. Our technical support staff are experienced in the installation, operation, and maintenance of all flow meters, and have hands-on field experience. They’re familiar with the meter intricacies and can help you get the most out of your measurement and meet your project goals.

Related Posts

Featured Posts

Small Package, Big Impact: The Importance of Desiccant Cartridge Maintenance

You’ve likely seen a desiccant cartridge, in the form of the small silica gel packet accompanying food products, or the activated carbon packet at the top of pharmaceutical bottles. It’s also commonly used in electronics and near sensors, especially for...

Choosing the Right Non-Contact Flow Meters: A Quick Dive into Radar and Laser Technologies

When measuring open channel flow wastewater and stormwater, non-contact flow technology is the ideal method, able to provide an accurate velocity and flow rate. Especially in the wet weather season, non-contact flow technology greatly benefits open channel...

Meeting BABA Compliance and Expanding Opportunities

Content Recorded and Published at WEFTEC in October 2024 In this episode of The Water Online Show: On Location, (now former) McCrometer President Pete Oveson dives into the company's story and recent developments shaping its future. He begins with an overview of...

Request More Information