Sour Service: A V-Cone Oil and Gas Application

If you’re in the oil and gas industry you’ve heard of sour service, a flow media composed of hydrogen sulfide (H2S) that is often found in natural gas, drilling, crude oil production, and even some wastewater applications. It’s also known for causing stress-induced cracking in certain metals, causing pipeline engineers to require heavy-duty materials that meet rigid specifications when working on a new or existing flow project.

The V-Cone® is an ideal flow meter for sour gas service, an application that often has demanding requirements that vary globally. We spoke with our channel partner AZ Flowtech, a metering and instrumentation company exclusively selling the V-Cone product line in Malaysia, to talk about their experience with sour service.

Sour Service Process Applications

In the oil and gas industry, sour gas applications occur in the processing of hydrocarbons from oil fields. About 20 – 30% of AZ Flowtech’s business deals with sour service applications, both liquid and gaseous. For liquid sour applications, the media is usually mixed with seawater, and for gas, the sour gas is composed of gaseous hydrocarbons.

Material Specifications

Common materials for sour service include duplex and super duplex stainless steels, and less commonly, low-temperature carbon steel with a special corrosion allowance. Historically, AZ Flowtech has had customers with wet sour applications opt for super duplex, and dry hydrogen sulfide applications request low-temperature carbon steel or duplex material. Material specifications adhere to NACE International guidelines for standard practice and test requirements.

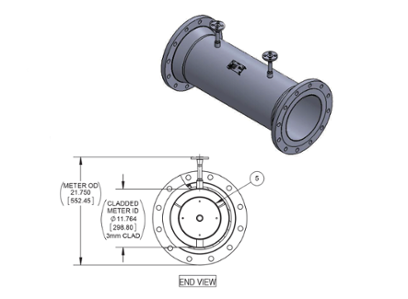

To meet material specs and stay budget-conscious, cladding a V-Cone pipe is another option pipeline engineers have requested, opting for low-temperature carbon steel with Inconel cladding that may save the expense of all-Inconel meters.

McCrometer’s Suggestions for Sour Service

McCrometer’s engineers aren’t specifically corrosion engineers, professionals that have niche expertise and thorough knowledge of implementing specific materials and practices to manage corrosion. However, our engineers are experts in the V-Cone, and will often make suggestions where they can foresee cost savings or lead time savings. Engineering the ideal custom V-Cone is a collaborative, consultative process that spans more than just specifications and paperwork!

Collaborating with the engineers on the end-user side of the project is what allows the McCrometer team to understand various project goals and ways that we can customize our product to meet the needs of oil and gas and industrial customers. To share the perspective of an end-user, we talked to a pipeline engineer from a prominent global oil and gas company and received his take on sour service.

A Pipeline Engineering Customer’s Perspective on Sour Service

There are many factors that are considered when deciding upon a material for a pipeline and flow meter; the pipeline engineer often collaborates with a metallurgist or material selection expert, as well as a process engineer, all of whom consider variables like flow media, pipeline pressure, temperature, and various industry standards that must be adhered to. During one offshore project containing a gas compressor line, the temperature was below 60 degrees Celsius with higher pressure near the wellhead itself, and lower pressure after the sour gas traveled to the processing system. It was deemed a sour service application at the platform due to the higher pressure and therefore higher partial pressure of H2S (PH2S), so the material of the pipeline needed to accommodate sour service throughout the pipeline. If one component of the process is sour service, all sour service compatible materials are specified for standardization.

Sour Service V-Cone Testing

Sour service materials are interchangeable; there is carbon steel that is non-sour service and one for sour service. Sour service stainless steel or duplex often isn’t much different than regular stainless steel or duplex – it’s all in the testing and certifications.

Stainless-steel V-Cones produced for an oil and gas application.

NACE International testing is required for sour service flow meters, including the normal non-destructive testing (NDT) typically required for duplex stainless steel. For certain materials like carbon steel, tests like hydrogen-induced cracking (HIC), sulfide-oriented induced cracking (SOHIC), etc. are required to verify hardness. Sour service also needs to adhere to the EN 10204 3.2 design code which necessitates a manufacturer’s inspection, 3rd party verification, Scanning Electron Microscope (SEM) inspection, accompanying certificate, and statement of compliance.

Choosing V-Cone for Sour Service

McCrometer’s pipeline engineering customer and AZ Flowtech both choose the V-Cone for sour service applications due to material customization, accuracy, and most of all – the minimal straight-run requirements.

From a design perspective, if a project has large compression lines, it’s difficult to meet straight-run requirements needed by other differential pressure technologies. Since sour service has a limited number of pricy materials available to construct both pipeline and flow meter, the V-Cone’s ability to save space and weight also reduces overall cost. The V-Cone’s minimal straight-run requirements are beneficial when pipeline engineers spec-in a more expensive metal for the V-Cone; the overall financial investment in a duplex flow meter is a lot less when the straight-run requirements are next to non-existent.

The variety of V-Cone material construction options has been a major benefit for McCrometer customers, as it allows them to maintain technical compliance as well as implement a cost-effective solution; that along with the V-Cone’s 25+ year lifespan makes it an investment meter pipeline engineers can rely on.

The V-Cone can truly be customized for a variety of sour service applications, to accommodate higher and lower pressures, temperatures, liquid or gaseous H2S, and various testing requirements. The V-Cone engineering team highly recommends a collaborative, consultative approach to learn about the project goals and application details, to best make recommendations about cost-savings, reduced lead time, product longevity, and overall benefit.

To learn more about the V-Cone for sour service, reach out to the V-Cone applications engineering team directly at vconerfq@mccrometer.com

Related Posts

Featured Posts

3 Reasons Why Budget-Focused Farmers Invest in Integrated Telemetry

Allocating budget to flow technology may seem unjustifiable when funds are tight; flow meters and their electronics may already be installed, giving no reason to replace or add additional units when the current solution is in fine working condition. However, flow...

Small Package, Big Impact: The Importance of Desiccant Cartridge Maintenance

You’ve likely seen a desiccant cartridge, in the form of the small silica gel packet accompanying food products, or the activated carbon packet at the top of pharmaceutical bottles. It’s also commonly used in electronics and near sensors, especially for...

Meeting BABA Compliance and Expanding Opportunities

Content Recorded and Published at WEFTEC in October 2024 In this episode of The Water Online Show: On Location, (now former) McCrometer President Pete Oveson dives into the company's story and recent developments shaping its future. He begins with an overview of...

Request More Information