Mag Meters for Water Transfer and Fracking Applications

Water Applications in the Oil and Gas Industry

The oil and gas industry has some of the harshest, most corrosive flow media a meter can measure; crude oil, slurries, hydrogen sulfide (sour gas), and more. These applications demand a durable meter to measure and report critical data to engineers and operators. However, another challenging application in the oil and gas industry demands durability and accurate flow measurement: water transfer.

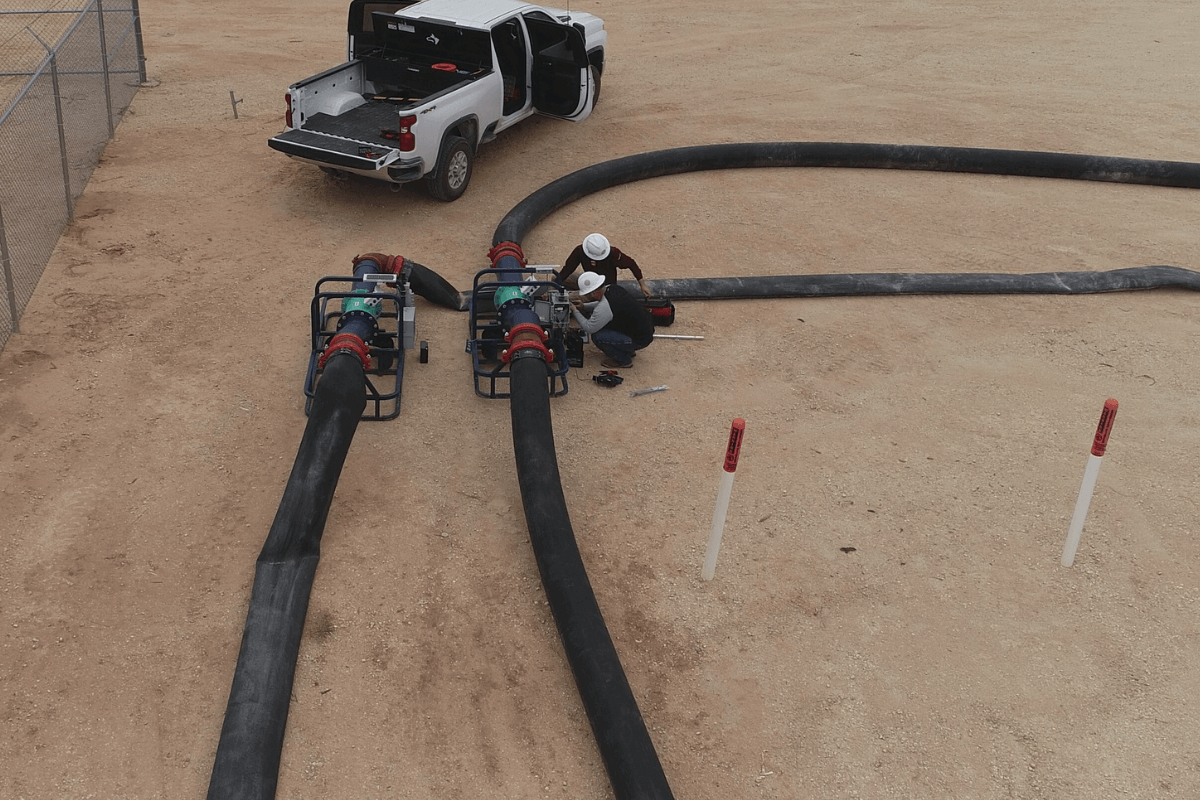

A water transfer operation.

What is Water Transfer?

Water transfer is a popular oil and gas application that involves a system of mobile pipelines connecting water sources, such as wells or other groundwater sources, with hydraulic fracking operations. Water transfer is often preferable to utilizing tanker trucks, which can be costly and operationally inefficient, especially if an operator requires a significant amount of water to support multiple fracking wells. Water transfer to frac ponds allows operators to deliver water to the fracking operation continually, which extends operating time and reduces costs, in addition to the overall convenience of the method.

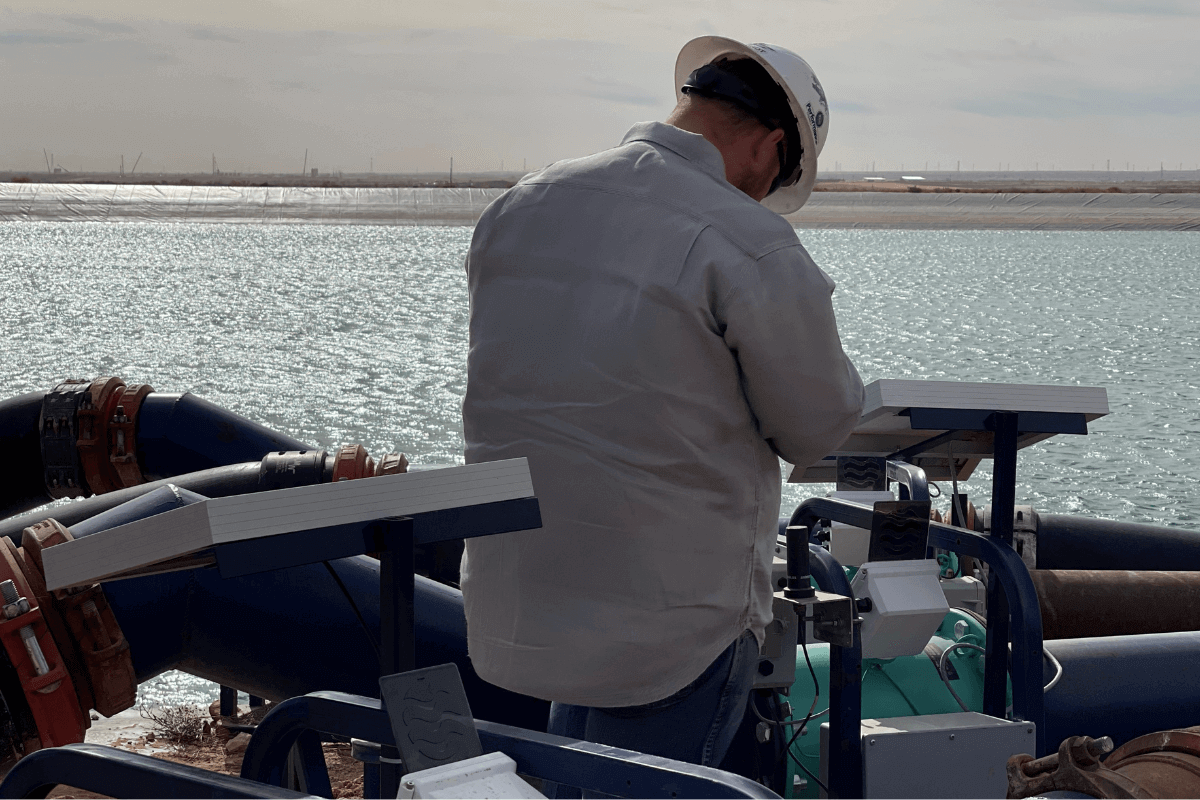

Water can be purchased from a farmer’s well or surface water source, or from a municipality, and stored locally to inject into the ground for fracking. Water is often stored in tanks or open-air pits called frac ponds, a manually dug pit with a rubber liner used for retaining that water.

Metering Points for Water Transfer Applications

The common metering points for water transfer applications are:

- Upstream source water transfer. Water transfer service providers often source the water and set the lay-flat pipe between the well or surface water source. There are often miles of lay-flat pipe between the water source and the frac pond, involving various terrain, roads, and wildlife. Metering at various points during the transfer process acts as a diagnostic tool, pinpointing any pipeline leaks, pump problems, or blockages. Accurate metering also allows for accurate billing as well; without multiple meters for this application, underbilling or overpaying may occur.

- Frac pond to wellhead. Fracking involves a specific recipe of water, chemicals, and sand injected from the wellhead into the shale formation. Precision is key here, as specific densities of the frac fluid are required to better penetrate the formations. The chemistry must always be correct and may need adjustment on the fly, especially when combining fresh frac pond water with recycled water from the flowback or production water.

A technician near a frac pond.

- Flowback water. This brackish, salty water is a mixture of frac fluid (saturated with chemicals), water, sand, and dirt particulates that flows back to the surface during and immediately after fracking. This water can be treated (often at an on-site or near-site water treatment area) and recycled for additional fracking efforts. Flowback water, especially the disposal component, is regulated by governing bodies such as the Environmental Protection Agency (EPA) and often the state, so an accurate flow measurement device that provides the necessary data to comply with those regulations is crucial.

- Produced water. The chemical composition of produced water and flowback may be similar in some cases, but produced water is naturally occurring water emerging from the shale during the extraction process. This flow media may contain dissolved hydrocarbons, minerals, gasses, and oil, and will flow through a separator and then water treatment to recycle as much as can be reused during the fracking process. Any produced water that cannot be recycled will then go to the disposal well. While some operators opt to truck their produced water to the disposal facility, some areas have an established hard pipeline that runs to the saltwater disposal well. There, the flowback and produced water (FPW) runs through multiple settling tanks, a separator, sometimes a reverse osmosis system, and then is metered as it flows into the disposal well. Disposal wells are highly regulated by the EPA and local governments, so implementing accurate, repeatable flow meters is beneficial to operators adhering to these directives.

The Importance of Accurate Flow Data

Flow data, when used properly, can positively impact water transfer operations. Data allows engineers and operators to better plan water transfer activities so water is available for fracking when the well is ready. Flow data also provides critical information about various aspects of pipeline integrity, indicating any leaks, failing pumps, and interferences that can hinder operational efficiency. Installing multiple flow meters, especially for longer distance transfers, is a simple method of leak detection and troubleshooting pipeline failures. Additionally, multiple metering points ensures that frac pad operators are receiving the water that they pay for, and transfer service companies can accurately bill for water sales and usage. Furthermore, metering each well prior to the lay-flat pipe will provide flow data about pump performance and well integrity. Many wells can only pump 2” – 4” (50.8mm – 101.6mm) worth of full pipe water out of a well, so many users choose to manifold multiple well pipelines together and connect that to a 10” (254mm) lay-flat pipe prior to transferring the water. Installing a flow meter on each well provides the seller with valuable data about their water sources.

Flow Meters for Water Transfer

The right flow measurement tools benefit water transfer operations and assist operators and engineers in meeting their project goals, financial goals, and conservation objectives. Choosing a feature-rich flow meter that meets the needs of the application at a fair price can be a challenge, so here are the top five features recommended for a water transfer electromagnetic (mag) flow meter:

1. Grounding rings. This is a major necessity when installing a mag meter for water transfer. Both sides of the mag need grounding rings, and a proper earth ground should be performed when installing a mag meter every single time. Grounding (see more on the topic here) helps to stabilize the signal of a mag meter and ensure its performance is unaffected by surrounding electrical noise and static electricity. For many years, improper grounding has plagued the Permian Basin, as operators did not realize the full extent to which grounding can adversely affect their measurement. Take the extra steps to ensure you are using grounding rings that are tied properly to an earth ground at each metering point.

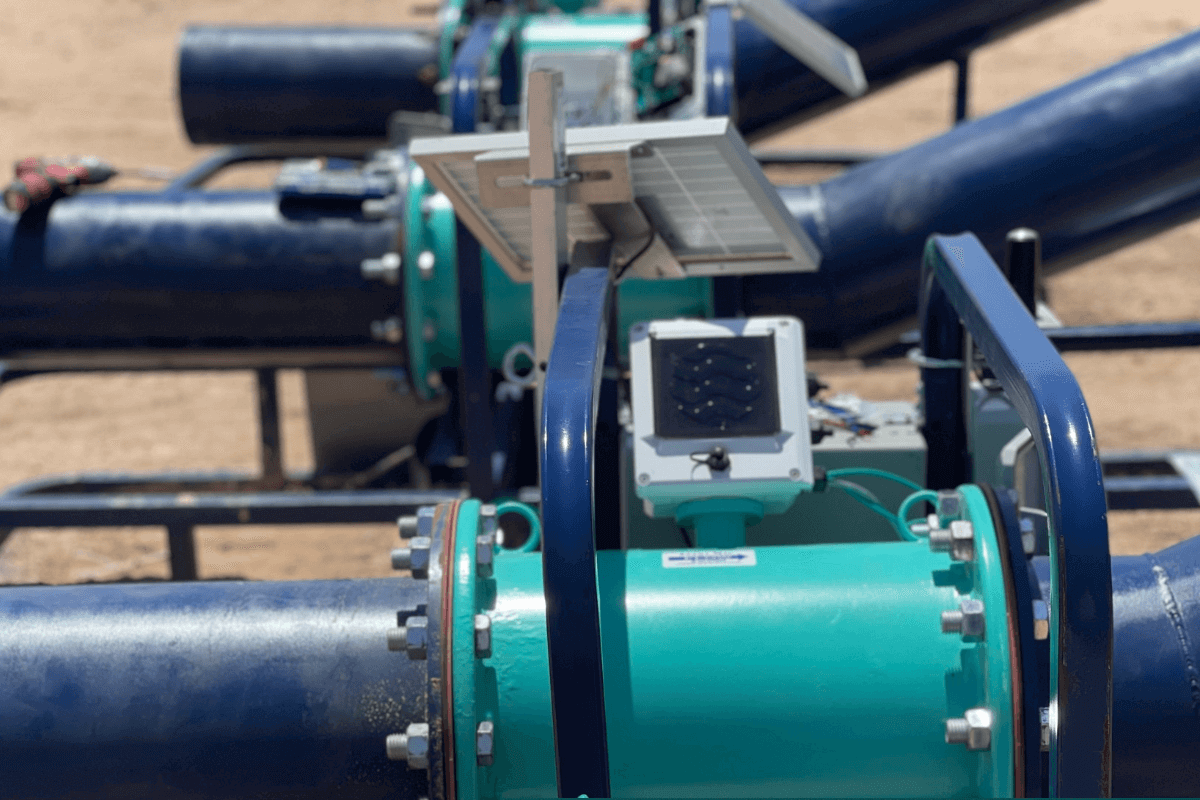

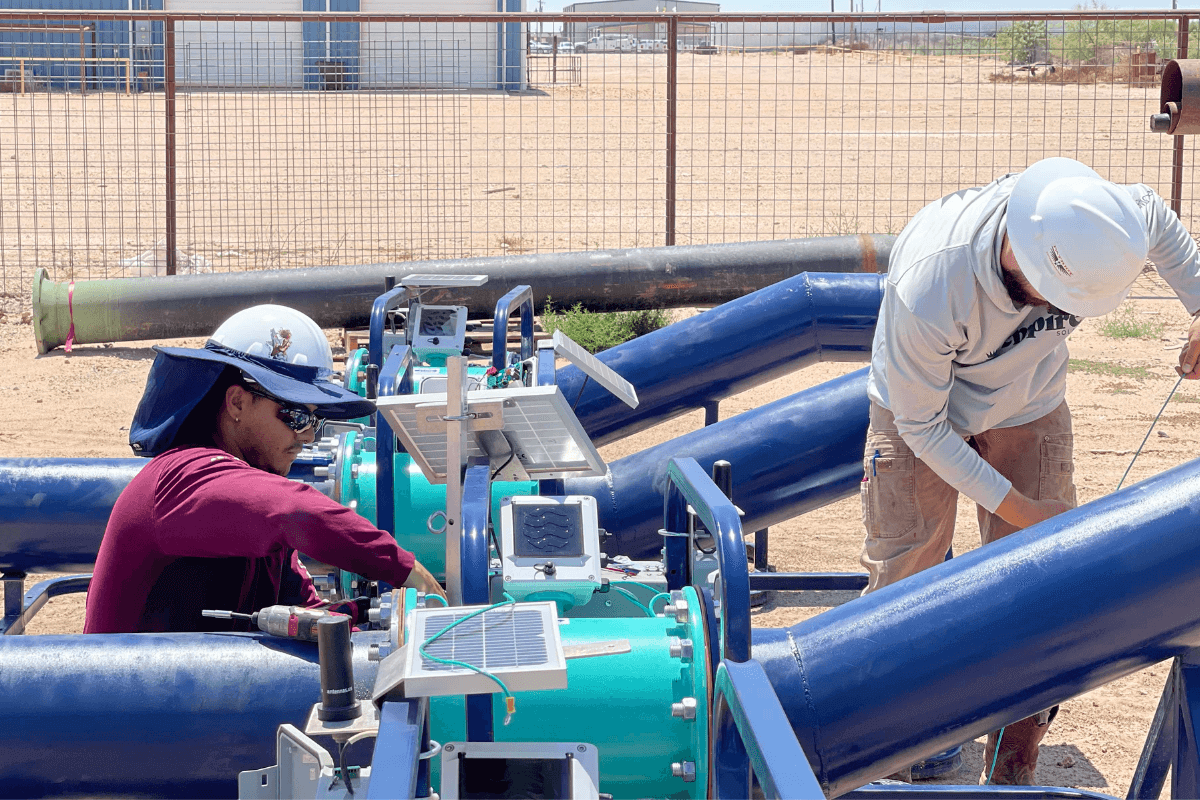

Technicians near the PE meter skid that includes multiple McCrometer Ultra Mags.

2. Durability. Most water transfer projects are short-term efforts, requiring equipment that can be packed up and transported to another location. Choosing a mag meter that can handle frequent installation, uninstallation, and being packed up in the back of a truck or trailer is necessary. Additionally, choosing a meter that can handle the flow media is also crucial, whether that’s raw water or FPW. Many traditional mag meters on the market contain a rubber or plastic liner that can delaminate, crack, or tear away from the meter, exposing the electrodes, wetting the electronics, or getting sucked into a nearby pump. Alternately, the Dura Mag® and Ultra Mag full-bore mag meters have the Ultraliner™, a fusion-bonded epoxy coating that is guaranteed for the lifetime of the meter and contributes to the overall durability and longevity of the meter.

Technicians near the PE meter skid that includes multiple McCrometer Ultra Mags.

3. Battery power. Lay-flat pipe can run for several miles between the initial water source and the frac pond, often in the middle of rural geographies with no reliable power source. Choosing a meter with dependable battery power is necessary; if a meter’s battery power source fails, there is no way to bill for water sold or report to the necessary governing bodies. The Dura Mag offers a 5-year full meter warranty including the battery (also a 5-year life!)

4. Reliable datalogger. A flow meter is only as good as the data it provides! Choose a mag meter that stores flow data in addition to the ability to send data to an integrated data system. The Dura Mag and Ultra Mag’s internal datalogger comes with 5 years of data storage to ensure that operators always have the historical data they need to quantify their water transfer efforts.

5. Output options. In addition to the battery power and datalogger, the ability to integrate flow data into the overall data management system is important. Choosing a mag meter with the desired output capabilities is important, as flow data aggregated alongside fluid levels and equipment performance information allows users to effectively manage all aspects of their water transfer.

Case Study: Patriot Environmental Liners

Patriot Environmental, LLC (PE) is an industry leader in geosynthetic liners, pit construction, secondary containment, and field asset mapping and monitoring solutions. PE integrates McCrometer’s mag meters into their meter skids, a packaged solution comprised of lay-flat pipe, 45-degree hard piping, water quality probes, level measurement, a solar-powered monitoring system, and multiple 10” (254mm) flow meters. These meter skids are transported to and from customers’ fracking sites and water transfer sources, auditing water that fracking customers are purchasing from landowners or municipalities. Additionally, these meter skids measure frac pond water pumped out of the pond or tank and into the frac itself, as well as the FPW being treated and recycled.

Technicians near the PE meter skid that includes multiple McCrometer Ultra Mags.

PE requires Modbus communication protocol to integrate into their existing system, thus opting for the feature-rich Ultra Mag with ProComm converter and DC power. While there are other full-bore mag meters on the market that offer the same power option and communication protocol, PE chose to adopt the Ultra Mag as their meter of choice due to the Ultraliner.

Whereas other manufacturers include rubber or ceramic liners, McCrometer’s epoxy Ultraliner is fusion-bonded to the meter body, eliminating the common problems associated with traditional liners. The Ultraliner is also what allows PE to install the Ultra Mag in multiple applications including upstream source water transfer, frac pond to well, flowback, and produced water measurement.

Related Posts

Featured Posts

Choosing the Right Non-Contact Flow Meters: A Quick Dive into Radar and Laser Technologies

When measuring open channel flow wastewater and stormwater, non-contact flow technology is the ideal method, able to provide an accurate velocity and flow rate. Especially in the wet weather season, non-contact flow technology greatly benefits open channel...

Meeting BABA Compliance And Expanding Opportunities

Content Recorded and Published at WEFTEC in October 2024 In this episode of The Water Online Show: On Location, (now former) McCrometer President Pete Oveson dives into the company's story and recent developments shaping its future. He begins with an overview of...

McCrometer, Inc. Announces Redesign of FlowComTM Digital Register

FOR IMMEDIATE RELEASE: September 3rd, 2024Contact: Aimee Davis, Vertical Marketing Manager, Agriculture McCrometer, Inc.AimeeD@mccrometer.com Hemet, Calif. – McCrometer, Inc., a globally recognized flow meter manufacturer, today announced the launch of their...

Request More Information