Get into the Groove: McCrometer’s Grooved-End Mag Meter

We’ll share the big news upfront! McCrometer’s integrated grooved-end mag meter is the only version on the market, and it’s revolutionary for a reason. Engineered to meet customer demand, this meter launched in January 2024 and is available for order now. This innovative meter is making a splash for oil and gas customers with water transfer and produced water flow applications.

Welcome to the electromagnetic flow measurement product suite, Field Mag!

Mag Meter Innovation for Oil and Gas Applications

As it pertains to the oil and gas industry, McCrometer’s V-Cone® takes the spotlight in most applications, measuring flow media such as wet gas, crude oil, and liquid natural gas. However, for water flow applications, the V-Cone isn’t always the right technology for the job. An electromagnetic flow meter is a durable, reliable measurement device that many operators and technicians implement for temporary flow applications such as water transfer and produced water.

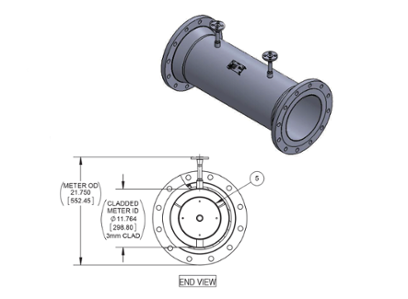

Operating based on Faraday’s Law of Electromagnetic Induction, McCrometer’s mag meters come in full-bore and insertion styles, and are known for their accuracy and transmitter options for data output. Many meter manufacturers offer a version of the mag meter, but McCrometer’s meters have a distinct feature unparalleled on the market known as the UltraLiner™. This proprietary, fusion-bonded epoxy is an alternative to the more common rubber liner prone to tearing or delamination, which can leave the meter’s electronics open to water intrusion, interfere with nearby pump functionality, and often render the meter defunct. The UltraLiner’s lifetime guarantee against tearing and delamination gives peace of mind to the user, and resists corrosive, high-pressure flow media common in produced water flow applications.

The UltraLiner has been an innovative benefit standard on meters such as the Ultra Mag® and Dura Mag® full-bore mag meters for more than 10 years. Popular in industrial and municipal applications, the mag meters have been installed in oil and gas applications flowing water as well, garnering specific customer feedback.

Technicians and engineers shared their feedback on installation and transportation, stating that while the Field Mag’s flanged ends were durable and adequate for long-term use, grooved-end fittings would expedite installation and decrease downtime for short-term water transfer applications. Additionally, the meter-mounted electronics were at risk of damage during frequent transportation between installation sites.

The Engineering of the Field Mag

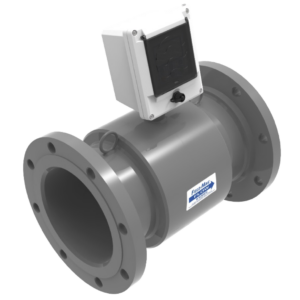

Based on this customer feedback, McCrometer began developing and testing an innovative version of the already popular mag meter, referred to as the Field Mag. To improve transportability, removeable feet accompany the Field Mag, easily slipped over the grooved ends, and bolted securely. This prevents the meter from rolling around in the back of a truck during transport, protecting the electronics and stabilizing the overall unit.

To accommodate the popular request for grooved couplings, the Field Mag features integrated grooved ends, a design unique to McCrometer due to the UltraLiner. The end connections feature the same seamless epoxy as the meter body, protecting the meter in its entirety and resisting corrosion and suspended solids in water transfer and produced water applications.

The Field Mag Models

McCrometer’s Field Mag flow meters are offered in two models. The Field Mag 3000 model features standard grooved end connections rated to 285 psi with ANSI #150 or #300 as other connetion options. The standard gray epoxy rated to 200°F and is accompanied by the ProComm Go™ converter electronics. This unit is battery powered with optional AC/DC and battery backup, and offers pulse, 4-20mA, telemetry output options and optional Class I, Division II compliance for hazardous locations. An integrated datalogger provides users with additional data recording and flow insight. Stainless-steel electrodes are standard, with Hastelloy as an option for users needing a higher corrosion-resistant alloy. This combination of electronics options and meter body construction makes it well-suited for water transfer applications and was in fact the basis for the Field Mag 3000’s engineering.

The Field Mag 5000 offers more sophisticated data collection and system integration, offering many of the above meter features and accompanied by the ProComm™ converter electronics. Powered by AC/DC, the unit offers Hart, ModBus, and 4-20mA output and optional Class I, Division II compliance for hazardous locations. The Field Mag 5000 offers ±0.5% or ±0.2% accuracy and features standard ANSI #150 or #300 flanged ends, but grooved ends may be requested from the factory. The electronics in-depth complexity and increased accuracy makes it well-suited to produced water applications that may require a higher-pressure ratings, temperature, and more precise flow measurements.

What Our Users Say about the Field Mag Series

McCrometer recruited Integrity Pump & Equipment as an early adopter of the Field Mag to beta test the innovative design. A handful of 6” (152.4mm) meters and one 10” (254mm) grooved end fittings coated in the 135°F high temperature epoxy were installed to existing lay flat hose that Integrity Pump had on hand.

Integrity Pump & Equipment President, Dusten Moore, took the meters to various water transfer job sites and installed them in various configurations to test the various beta meters numerous configurations.

“These meters are much lighter and easier to maneuver, reducing the overall installation time and general hassle of dealing with the meters,” Moore reports. “The feet that are provided with the Field Mags meter definitely give the meter body stability, and it is great that they are raised a few inches off the ground to accommodate the installation of the bolts. Overall, customers have had no issues with fitment. The spacing on the grooved fittings was accurate and easy to mate to the adaptor via the grooved coupling. These meters are much lighter and easier to maneuver, reducing the overall installation time and general hassle of dealing with the meters without sacrificing our working pressure of 285psi when compared to the heavier Flanged meters with additional flange to Victaulic connectors.”

McCrometer’s Research and Development team adopted the feedback on the feet height and redesigned the component to accommodate the bolt installation. Additional users have reported a general customer consensus of enthusiasm about the technology and design, especially over the prospect of avoiding the added expensive of installing flange to grooved fitting adapters.

Getting Your Field Mag

These highly anticipated flow meters are currently available for order and will officially launch January 2024! For additional information about this product series, reach out to your authorized flow meter representative, your McCrometer Regional Sales Manager, or directly to the factory.

Related Posts

Featured Posts

Small Package, Big Impact: The Importance of Desiccant Cartridge Maintenance

You’ve likely seen a desiccant cartridge, in the form of the small silica gel packet accompanying food products, or the activated carbon packet at the top of pharmaceutical bottles. It’s also commonly used in electronics and near sensors, especially for...

Choosing the Right Non-Contact Flow Meters: A Quick Dive into Radar and Laser Technologies

When measuring open channel flow wastewater and stormwater, non-contact flow technology is the ideal method, able to provide an accurate velocity and flow rate. Especially in the wet weather season, non-contact flow technology greatly benefits open channel...

Meeting BABA Compliance and Expanding Opportunities

Content Recorded and Published at WEFTEC in October 2024 In this episode of The Water Online Show: On Location, (now former) McCrometer President Pete Oveson dives into the company's story and recent developments shaping its future. He begins with an overview of...

Request More Information