Flow Straighteners vs. Straightening Vanes: Similarities and Differences

Straightening vanes and flow straighteners, in tandem with propeller meters, have been an important component of flow measurement in the agriculture industry – and for a good reason. Typically installed near flow disturbers or in short straight-run applications, flow straighteners and vanes reduce swirl and assist propeller meters with obtaining an accurate flow reading.

So, what’s the difference between a flow straightener and straightening vanes, and which option is the best for your ag application? It’s actually dependent upon your choice of flow meter and your application demands.

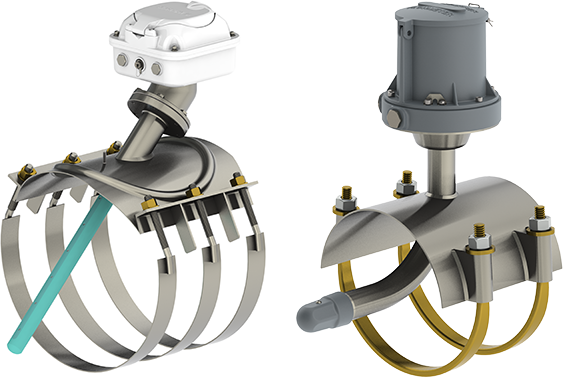

McCrometer’s Straightening Vanes

McCrometer has offered straightening vanes for almost as long as the Mc®Propeller has been on the market. The most popular version is also the most cost-efficient option, the bolt-in tri-vanes. Simple to install, the tri-vanes don’t come with a pipe, so they can be used with any existing pipe. For simple installation instructions, check out our YouTube video.

Similar to the individual tri-vanes, McCrometer also offers pipes with hex vanes for customers who prefer vanes welded directly into a pipe for convenience.

McCrometer’s Flow Straighteners

McCrometer began offering the FS100 Flow Straightener™ in 2006, which greatly reduced the straight-run requirements for numerous customer applications. Requiring only 1.5 diameters upstream straight-run pipe, the FS100 borrows its design from the V-Cone®, combining the self-conditioning cone design with the existing hex vanes.

The FS200 Flow Straightener™, released in 2019, is an engineering innovation developed in response to customer demand. The square shape of the FS100 requires a larger pipe cutout for installation compared to what’s required for a saddle-style McPropeller; this larger cutout can cause sealing and leaking issues in large line sizes. The FS200 was engineered to fit 10” and 12” diameter line sizes and can be inserted into the same cutout as the saddle-style McPropeller, eliminating the need for a larger cutout and potentially causing sealing and leaking issues. This design is especially helpful for retrofits where meters were originally installed but flow straighteners were not, eliminating the need to cut additional pipe to install a flow straightener.

The FS200 Flow Straightener is often implemented for large pipelines in applications like half-mile pivots that are pumping a significant amount of water, or other McPropeller and Water Specialties® applications where the line size is 10” or 12” diameter.

Custom Solutions for Flow Straightening

Whereas the FS200 Flow Straightener was developed based on popular customer demand, other solutions have been developed to provide a solution for a tough application.

In one instance, a Colorado well driller approached McCrometer to solve a complicated project challenge. A local golf course was ready to set their pump at the well and hook up to the discharge pipe but wasn’t ready to install a meter just yet. In order to assist the end-user in meeting their deadline for the pump project, McCrometer provided a longer flow tube and incorporated the FS100 Flow Straightener. The customer was able to install the straightening tube, get their pump project finished, and install a saddle-style McPropeller MO300 model at a later date. The meter is still operating at that location, ten years after the initial installation.

McCrometer is happy to take on tough applications and provide custom solutions when there’s a critical need for one.

Advice When Implementing a Flow Straightening Solution

When choosing to implement a flow straightening solution, consider your application and pipe diameter – if you have the distance and pipeline available, you may not even need a flow straightener! However, if you have a short pipeline or common flow disturbers like backflow prevention valves and butterfly valves, flow straighteners and vanes are an important component in ensuring your meter can read flow accurately. The FS100 Flow Straightener is a convenient option as it can be installed directly downstream of a backflow prevention valve and will condition the flow off the pump and valve.

If you’re a contractor testing out pumps for performance, the flow tube with FS100 installed is a very useful, all-encompassing product that can be used on many pumps and is a more cost-efficient option compared to an ultrasonic.

Both the FS100 and FS200 Flow Straighteners are very durable pieces of equipment, ideal for any application employing propeller meters. As it does intrude in the line, the flow straightener is not recommended for use in surface water measurement or applications with too much debris, as any moss or vegetation in the line can clog vanes.

Ultimately, choosing between each of the styles of flow straighteners and vanes is dependent on your application setup and chosen flow meter. For example, a saddle-style propeller meter doesn’t come with a pipe, so the vanes aren’t applicable unless a customer opts to purchase a tube to mount the meter on (which some do).

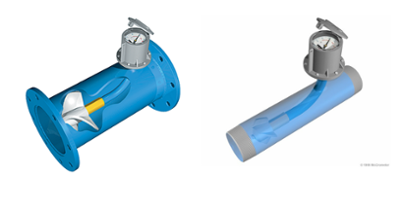

Now, if an irrigator purchases an MF100 or MT100 (pictured below), these are tube-style meters; so, if there is an upstream disturber like a valve or elbow, it makes more sense to have McCrometer weld in vanes.

The MF100 (left) and the MT100 (right).

Alternately, if an irrigator wants to purchase a saddle-style propeller and not an accompanying tube, purchasing an FS100 or FS200 Flow Straightener can solve flow disturbances and help meet project needs.

McCrometer is Here to Help

We know this can seem confusing – we have a lot of model numbers and even more combinations of meter model and flow straighteners and vanes. Luckily, we’re always here to help and have experts at our factory who can help assess your needs and recommend a meter and flow straightener or vanes that will work for you and your flow application.

Visit our product pages to learn more about our flow straighteners, and if you’re ready to move forward with your metering project, request a quote!

Related Posts

Featured Posts

Get into the Groove: McCrometer’s Grooved-End Mag Meter

We’ll share the big news upfront! McCrometer’s integrated grooved-end mag meter is the only version on the market, and it’s revolutionary for a reason. Engineered to meet customer demand, this meter launched in January 2024 and is available for order now. This...

Produced Water and Blending Flow Meter Use Case

Produced Water is a byproduct of oil production. Whether it is a byproduct of flow back or the water component of the oil separation process, produced water can be a difficult measurement point but is a very important part of the process. Several parameters make it...

Get your Groove on Now: McCrometer’s Grooved-End Mag Meter Now Available

It is time to get your Groove On. McCrometer has released their innovative Electromagnetic Flow Meter with integrated Grooved End connections. Are you tired of bolting on extra flanges with Victaulic end connections welded to them? It is time consuming and makes an...

Request More Information