District Heating in France: A V-Cone Customer Success Story

The V-Cone® is widely known for its success as a metering solution in the oil and gas industry, but it’s also a burgeoning solution for many industrial applications, including district steam. The V-Cone’s tolerance for a range of flow conditions and media, as well as available customization, make it a viable, lasting solution for many unique new and retrofit steam applications.

McCrometer’s French channel partner, Fuji Electric France, sought the V-Cone’s benefits when working with their customer, Coriance Group, on a district heating flow project from 2018 – 2020. The project proved to be tricky, but collaboration between McCrometer, the channel partner, and the end-user accelerated the project to completion in late 2020.

The V-Cone Steam Application

Coriance Group provides steam heating and cooling to customers north of Paris, France through a system of boilers and furnaces. Additionally, Coriance receives steam from other heating companies in the area. The flow rate fluctuates based on customer demand and seasonality, with late fall to early spring being their high flow season for steam heating.

The V-Cone was chosen for this project due to the minimal-to-no straight-run required, as the installation site was beneath a roadway, and space was limited. Optimized for confined spaces, the V-Cone was easily integrated into the end-user’s existing layout, saving them the cost of repiping. Orifice plates and vortex meters would be able to measure the steam in this situation, but the orifice plate’s straight-run requirements would have demanded additional piping and space that simply didn’t exist, and the application’s flow range would have necessitated two vortex meters. Overall, the V-Cone was an easy choice to provide rangeability and accuracy in a legacy bi-directional flow application tight on space.

The entrance to the small room containing the pipeline for the V-Cone project.

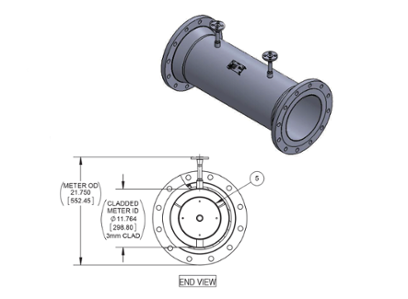

Coriance Group’s metering application involved 202°C steam produced by two furnaces needing a bi-directional V-Cone to measure both forward and reverse steam, in a range of flow rates. Depending on seasonality and customer demand, Coriance both sends and receives steam using the bi-directional pipeline. For the allocation aspect of this flow application, accurate steam measurement was a project requirement for Coriance – especially accuracy over a wide flow range. The project’s flow range was initially overestimated by the end-user to include a high flow rate of 120,000 kg/h and a velocity of 190 ft/s, with a 19:1 turndown requiring stacked transmitters.

Initial Overestimation

The initial process data provided to the McCrometer application engineers overestimated the flow range resulting in a V-Cone manufactured and installed in the customer’s pipeline but not adequately measuring the steam. While gross overestimation is not a common occurrence, it does happen intermittently; engineers want to cover their bases and avoid head loss at the high end of their flow rate. Overestimating the flow range prevented the V-Cone from measuring the actual flow. Coriance Group’s flow project comprised an intricate, custom solution involving stacked, bi-directional DP transmitters with standard impulse lines. Accurate process data was crucial to get the end-user a beneficial metering solution in place.

The first V-Cone manufactured for the project was installed in early 2019, and by summertime, it was clear that the steam wasn’t being measured adequately. Coriance Group, along with channel partner Fuji Electric France, contacted McCrometer’s engineering team to conduct some remote troubleshooting and problem-solving. By taking the flow application’s surrounding variables into consideration, including condensate pots, impulse lines, valves, environmental temperature, and more, the problem revealed itself to be the incorrect initial process data and the resulting ineffective flow meter.

The high flow rate was initially overestimated at 120,000 kg/h. In reality, the high end of the flow range was 63,000 kg/h – half of the overestimation. Additionally, the initial velocity was 190 ft/s, and the second sizing contained a velocity of 150 ft/s. The first V-Cone’s overestimation of high flow and the wrong turndown affected the V-Cone’s ability to measure the low flow that this application experienced. The V-Cone does claim a 10:1 turndown, but in this case, 4 transmitters were needed to accurately measure the range of flow in both directions.

The Right V-Cone Solution

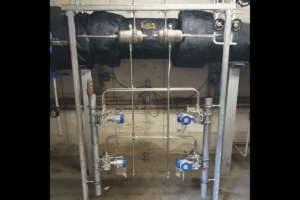

Two of McCrometer’s V-Cone experts assisted greatly in observing the complications with the initial V-Cone produced for Coriance Group’s steam project, and once the second flow meter was in place in January of 2020, the meter performed as desired, measuring the bi-directional flow without issue.

The successful bi-directional V-Cone with 4 transmitters to measure forward and reverse flow at a high turndown.

Challenging flow applications often require collaboration between the meter manufacturer, local channel partner, and the end-user in order to fully understand the process conditions, surrounding machinery acoustics and frequencies, and other details. McCrometer is proud to have assisted customers with V-Cone installations for more than 30 years.

There are many variables to consider when customizing and engineering a V-Cone, making communication and data a key factor in project success. McCrometer is pleased to have provided a successful V-Cone solution for Coriance Group and recognizes both the dedicated staff at Coriance Group as well as Fuji for their collaboration and partnership during the project.

Future V-Cone Projects

For other customers or engineers looking at a V-Cone solution for an upcoming flow project, we encourage early and frequent communication with McCrometer or your local McCrometer channel partner to take advantage of our team’s expertise with the product and flow measurement in general.

To search for your local McCrometer channel partner, visit our representative partner search on our website. To speak directly with our V-Cone applications engineering team about your future V-Cone project, email vconerfq@mccrometer.com.

Related Posts

Featured Posts

Choosing the Right Non-Contact Flow Meters: A Quick Dive into Radar and Laser Technologies

When measuring open channel flow wastewater and stormwater, non-contact flow technology is the ideal method, able to provide an accurate velocity and flow rate. Especially in the wet weather season, non-contact flow technology greatly benefits open channel...

Meeting BABA Compliance And Expanding Opportunities

Content Recorded and Published at WEFTEC in October 2024 In this episode of The Water Online Show: On Location, (now former) McCrometer President Pete Oveson dives into the company's story and recent developments shaping its future. He begins with an overview of...

McCrometer, Inc. Announces Redesign of FlowComTM Digital Register

FOR IMMEDIATE RELEASE: September 3rd, 2024Contact: Aimee Davis, Vertical Marketing Manager, Agriculture McCrometer, Inc.AimeeD@mccrometer.com Hemet, Calif. – McCrometer, Inc., a globally recognized flow meter manufacturer, today announced the launch of their...

Request More Information