Class 1, Division 2: What a Certified Meter Can Do for Your Flow Application

Operators and engineers in the municipal wastewater industry know that Class 1, Division 2 (C1D2) certified equipment is often required for certain areas of operation, particularly in hazardous locations. Choosing the right flow meter that is certified to C1D2 can bring value to the flow application, protection to equipment, and budget savings to the bottom line – in addition to complying with safety regulations.

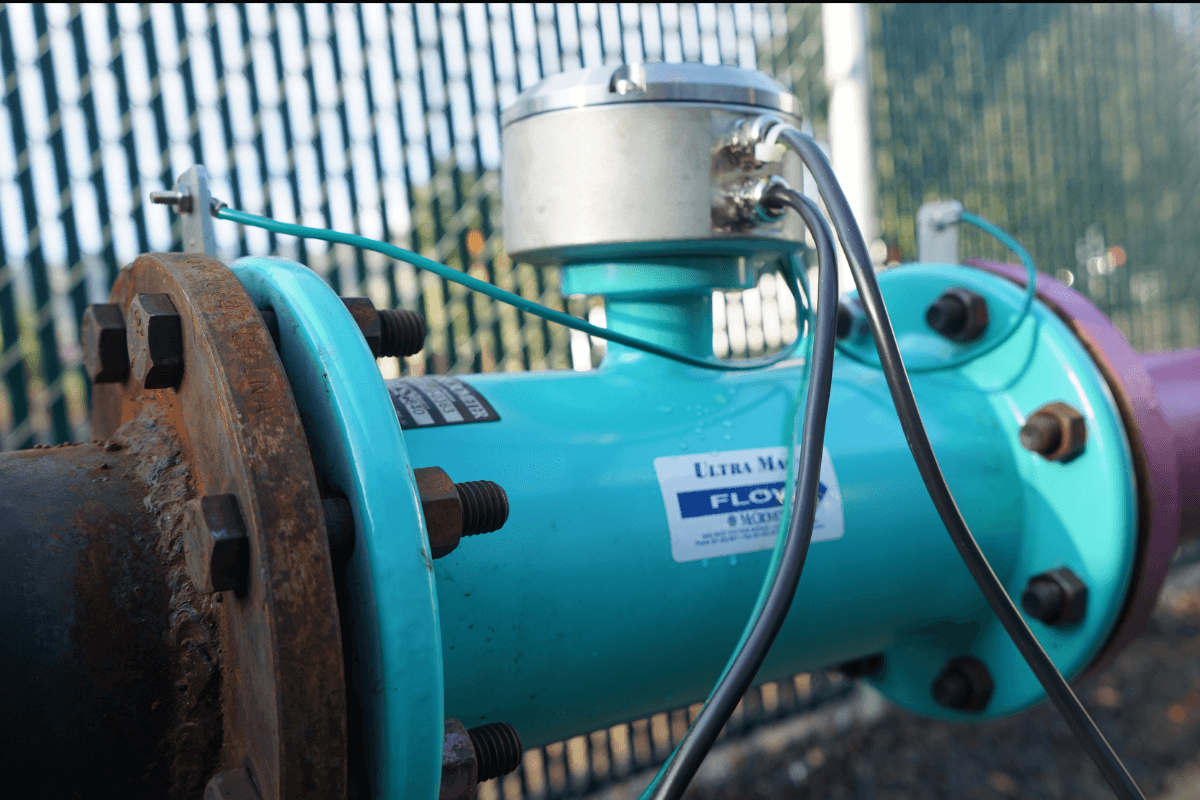

A Class 1, Division 2 certified Ultra Mag installed in a municipal setting.

What is Class 1, Division 2?

C1D2 describes hazardous locations where there is the potential presence of explosive gasses, vapors, dust, or fibers that might ignite due to equipment, wiring, or other variable in the vicinity. Since electrical equipment has the possibility to ignite surrounding fibers, gasses, and dust, C1D2 regulations have been outlined by the National Fire Protection Association (NFPA) and adopted by OSHA (Occupational Safety and Health Administration).

Where does Class 1, Division 2 Apply?

C1D2 applies to industries such as municipal wastewater, whose treatment and collection facilities, septic tank effluent pumps, pumping station wet wells, and other operations contain gasses from raw sewage. Industrial flow applications may require C1D2 equipment as well, such as chemical or petrochemical plants that often use steam distribution, acetone, methane, butane, or another media that is hazardous in the line.

Pulp and paper plants frequently have wastewater treatment facilities on-site, which mirror many of the same municipal water applications and requirements as well. Other industrial companies which employ fuel sources as inputs to their processes may require C1D2 equipment if running flow media such as methane or butane.

McCrometer Meters for Class 1, Division 2

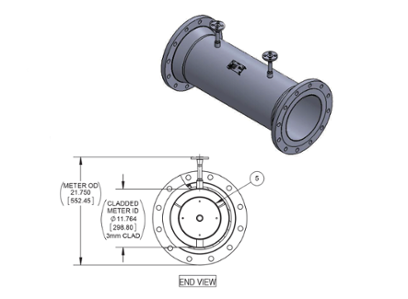

For flow applications requiring Class 1, Division 2 certification, McCrometer’s FPI Mag® and Ultra Mag® fit the bill. It’s important to note that the primary element itself (the meter body and electrodes) hold no concern for performance in hazardous locations; the material makeup of both meters is non-combustible in nature. The electronics associated with a flow meter are most often the concern when dealing with Class 1, Division 2 settings. Both the FPI Mag and the Ultra Mag meters are accompanied by the ProComm converter, which is approved for use in hazardous locations.

As Division 2 specifies open-air spaces with potentially hazardous surroundings, the FPI Mag offers many desirable value-added features and design benefits, especially in tight quarters. The FPI offers hot-tap installation, an advantageous element that makes the meter an ideal solution for retrofit projects. In locations where space is at a premium, the FPI Mag’s minimal straight-run requirements eliminate the need to repipe an existing setup or arrange for costly construction to cut pipe and weld flanges.

For retrofit projects replacing a full-bore meter, the Ultra Mag is ideal. Custom lay-lengths and little-to-no straight-run pipe required, the Ultra Mag is a great choice for operators and engineers wanting accuracy, reliability, and convenience.

McCrometer Meters for Class 1, Division 1

In addition to the C1D2 certified mag meters, the V-Cone® is another approved meter for hazardous locations. The primary element itself is inherently non-hazardous in its design; there are no electronics or circuits in the meter itself that could potentially spark. McCrometer’s V-Cone can be paired with any compatible and certified transmitter of the customer’s choosing when being specified into a flow project at a hazardous location.

Given the versatility of transmitter options, the V-Cone has the potential to meet both C1D2 and Class 1, Division 1 location requirements. While Division 2 specifies an open-air environment, Division 1 stipulates an enclosed environment.

The flexibility to pair any compatible, certified transmitter with the V-Cone allows customers to receive the flow monitoring equipment needed to meet exact project requirements.

Hazardous Locations, Compliant Meters

McCrometer understands that flow projects are often complex with a multitude of variables and inputs to consider. We aim to engineer durable, reliable metering equipment that meets our customers’ project needs and provides them with the flow data needed to make informed decisions about daily operations.

Certifying our world-class flow meters to Class 1, Division 2 is just one of the certifications and approvals we’ve worked to provide for our customers. If you have a unique flow project and need a custom solution to meet your metering needs, reach out to the McCrometer product management team at customerservice@mccrometer.com.

Related Posts

Featured Posts

Small Package, Big Impact: The Importance of Desiccant Cartridge Maintenance

You’ve likely seen a desiccant cartridge, in the form of the small silica gel packet accompanying food products, or the activated carbon packet at the top of pharmaceutical bottles. It’s also commonly used in electronics and near sensors, especially for...

Choosing the Right Non-Contact Flow Meters: A Quick Dive into Radar and Laser Technologies

When measuring open channel flow wastewater and stormwater, non-contact flow technology is the ideal method, able to provide an accurate velocity and flow rate. Especially in the wet weather season, non-contact flow technology greatly benefits open channel...

Meeting BABA Compliance and Expanding Opportunities

Content Recorded and Published at WEFTEC in October 2024 In this episode of The Water Online Show: On Location, (now former) McCrometer President Pete Oveson dives into the company's story and recent developments shaping its future. He begins with an overview of...

Request More Information