Basic Water Transfer Flow Meter Use Case

Water Transfer and the Associated Use Cases

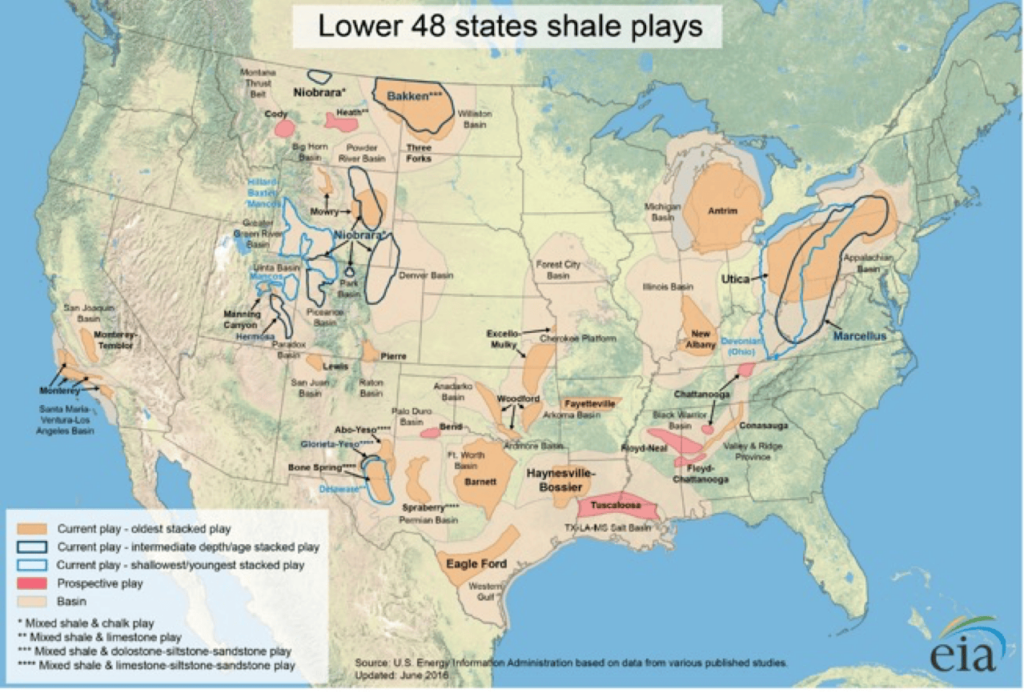

The water transfer industry evolved to support one of the Enhanced Oil Recovery (EOR) methods called hydrofracking. Hydrofracking or “fracking” involves the injection of a mixture of water, sand, and proprietary chemicals at high pressure and high volumes over the period of typically 2 weeks. The high pressure frac fluid “fractures” the shale formation as the fluid intrudes into the formation breaking it up and allowing the trapped oil the means and a path to allow the extraction of oil that otherwise is not available for use. There are numerous shale “plays” across the world but the largest one globally is the Permian Basin located in west Texas and New Mexico. There are numerous other shale plays in the United States including the Eagle Ford in south Texas, the Bakken up in the Dakotas, the Marcellus and Utica Shales in Western PA, as well as the DJ Basin in Colorado.

The water transfer industry is there to support the fracking operations. Once a frac starts, it runs continuously for typically a two week period. Again, once it starts, it does not stop until it is complete. Consequently, massive volumes of water must be at hand prior to the start of the operation. In many places, especially the Permian Basin, the area is very arid as it is in the desert. As one can imagine, water becomes a premium in the desert. Many of the farmers in this area have been approached by the oil producers who are asking to purchase their water. Often, the oil producers will even drill water wells and install pump packages and lease them to the farmer while they purchase the water drawn from their wells. Some farmers install their own wells and will have a larger frac water pit dug on their property and have it lined to keep the water from leaking back into the soil.

I have seen a 25,000 acre farm with 31 water wells installed on the property. These wells fed a 500,000 barrels frac pit. Each barrel is equal to 42 gallons of water. When the farmer sells the water to the oil producers, they are being paid between $.50 to $1.50 per barrel. The water is metered in several locations. There are typically several smaller lines (3”-4”) feeding into progressively larger lines (10”-14”) that feed the pit to fill it up. When a frac is being planned, the water transfer companies deploy lay flat hose to transfer the water from the frac pit to the site which can be several miles away. The farmer will typically meter the water as it leaves their pit and the water transfer companies will meter it as well and will install meters along the route to ensure they can track the flow of the water from the pit to the site.

The meters used in these applications were mechanical many years ago but have shifted to electromagnetic flow meters over a decade ago. Of these mag meters, most have been battery powered flanged meters with pulse outputs that are rarely used. The most important pieces here are the battery power and the totalizer. The operators need to capture the total of the meter before they start and may monitor it in the interim but the final numbers are certainly important as well. If they cannot quantify how much water they have moved, they cannot get paid for it. remember that if a meters fails 2 days into a 14 day frac, they do not get paid for the other 12 days.

Once the frac is complete, they drain the lines, reel up the lay flat hose, load the meters back into the truck, and redeploy to the next job. Occasionally there are breaks between jobs that can allow for cleaning, inspection, and maintenance of the meters however this is not always the case. Most people are quite rough with these meters.

Traditionally these meters have been very heavy and cumbersome due to the added weight of the flanged to Victaulic meter adapters and the protection installed by customers and the sales channel to keep the electronics from being damaged. If you look closely at some of these meters, the weight of the meters can be effectively doubled with the addition of the flanges, bolts, and electronics protection.

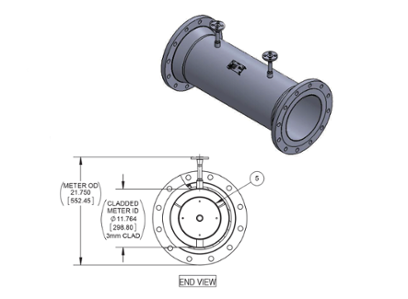

Our solution shown below not only does not need the extra weight from the bolt on solutions, it also decreases the weight versus our standard flanged meter by integrating the grooved ends directly onto the meter. In fact, we are the only manufacturer that currently offers this design. The other manufacturers use a rubber or ceramic liner that must protrude outside the confines of the flow tube and wrap around the face of the flange. They cannot do that with the grooved end connections which precludes them from making their own version.

The Basic Water Transfer Meter the following configuration and is based on a 10” meter since this is the most popular:

FM310-VSMB

- FM3– ProCommGO electronics

- 10– 10” meter

- V– Victaulic “Grooved End Connection”

- S– Stainless Steel Electrodes

- M– Meter Mounted Electronics

- B– Battery Powered Meter

The majority of the water transfer operations (70%) are handled using the meter shown above due to cost and the lesser need for sophisticated metering. They read their totals from the totalizer on the display and may utilize the built-in data logger to quantify rates and totals throughout the life of the project.

For additional information about this product series, reach out to your authorized flow meter representative, your McCrometer Regional Sales Manager, or directly to the factory.

Related Posts

Featured Posts

Choosing the Right Non-Contact Flow Meters: A Quick Dive into Radar and Laser Technologies

When measuring open channel flow wastewater and stormwater, non-contact flow technology is the ideal method, able to provide an accurate velocity and flow rate. Especially in the wet weather season, non-contact flow technology greatly benefits open channel...

Meeting BABA Compliance And Expanding Opportunities

Content Recorded and Published at WEFTEC in October 2024 In this episode of The Water Online Show: On Location, (now former) McCrometer President Pete Oveson dives into the company's story and recent developments shaping its future. He begins with an overview of...

McCrometer, Inc. Announces Redesign of FlowComTM Digital Register

FOR IMMEDIATE RELEASE: September 3rd, 2024Contact: Aimee Davis, Vertical Marketing Manager, Agriculture McCrometer, Inc.AimeeD@mccrometer.com Hemet, Calif. – McCrometer, Inc., a globally recognized flow meter manufacturer, today announced the launch of their...

Request More Information