Advanced Water Transfer Flow Meter Use Case

As mentioned previously in the Basic Water Transfer Use Cases Blog, most water transfer operations (70%) are handled using battery powered flow meters. They read their totals from the totalizer on the display and may utilize the built in data logger to quantify rates and totals throughout the life of the project.

There is a smaller set of water transfer companies that not only deploy the pumps, meters, and lay flat hose; they also manage the data coming from the pumps and meters. They build sophisticated solar panel powered systems with electronics to receive Modbus data from the meters and transmit the data to the cloud through a cellular modem. The resultant data can be viewed from numerous sources with varying frequencies. It could be an external website through a login, perhaps a daily text message or email, or even through a cell phone app with interactive geo data indicating location and status of equipment. These more discerning users are looking for Modbus data and reliability.

These more discerning users prioritize near real time data capture and inform themselves and their customers. To them, data is king and they regularly use data to drive decisions. For instance, they can remotely monitor the status of their projects and provide charts and graphs with the resulting data. They can quantify the amount of water that is in transit is sufficient to meet their project deadlines. They can receive alarms indicating loss of flow, meter failure, or pump failure. All this data enables them to see remotely what previous operators were paid to monitor by visiting the meters and pumps regularly physically. This increase in efficiency saves money and gives both the operators and the providers more comfort knowing that their project remains on track.

In order to accommodate these more stringent data capture requirements, a more sophisticated meter electronics package is required. Sophistication results in a greater need for power. Below is a breakdown of the different power configurations and their strengths and weaknesses.

Battery Power –

- Operation – When a battery is your only source of power, you have less power available to drive the coils used to generate the magnetic field which results in a weaker magnetic field for measurement. The weaker magnetic field results in a decreased accuracy. Battery powered meters will typically power on and take a reading every 15 seconds. It will then power down and wake up 15 seconds later for another reading. The readings are then averaged over time and a flow rate is generated. Most fluid flow is relatively constant so this can be acceptable in some instances. The cycle on and off methodology preserves battery life and yields a reading that is typically +/- 1%. In a scenario where 1% is an acceptable accuracy specification with no output from the meter, this may be acceptable. The Field Mag 3000 has an accuracy of +/- 1.0%.

- Outputs –

- Pulse – If you need to output a pulse that indicates flow rate, there is not much change to battery life.

- 4-20mA – Generating a passive 4-20mA output may decrease battery life slightly but the drain is not anything near what it is for Modbus or other communications protocols.

- Modbus – Modbus is the power hog of flow meter outputs. The protocol yields many useful parameters and in such a manner that they cannot be manipulated however, the constant handshake between the output and the control system or RTU takes a large amount of power.

- Some battery powered meters have Modbus outputs but the functionality comes at a high cost in power consumption. A battery that previously lasted months, may only last weeks or months if Modbus is enabled.

Mains Powered Units

AC or DC Power –

- Operation – Full coil excitation capacity is present resulting in larger coils and magnetic fields required for maximum accuracy and stability of readings. Instead of measuring every 15 seconds as the battery powered meter, most meters measure 5-10 times each second with mains power applied. Increased accuracies are reflected as well. For instance the Field Mag 5000 has an accuracy of +/-0.5% or even +/- 0.2% with a special calibration.

- Outputs – The only restrictions on outputs are related to what you have purchased and the meter configuration. For example a meter may be able to do Pulse, 4-20mA, and Modbus concurrently.

Solar Powered Units

DC Power –

Operation – Solar power setups provide DC power during daylight hours and will send the excess power to recharge a battery pack that steps up during darkness and carries the load until daylight power is available. For all intents and purposes solar powered setups operate the same as DC powered units since the solar system, solar panel with controller and subsequent battery setup, is essentially a DC power source.

Integration into Telemetry Systems

Telemetry is the vehicle that moves meter flow data into the cloud and then to a cell phone or computer. In the Permian Basin most of these setups include a solar panel, solar panel controller, RTU of some sort, and a cellular modem. These packages provide power for the components. Like I mentioned, the higher end providers include some sort of portal for the customer to log into or even a mobile app that gives them a nice interface to retrieve the data and provide text messages for alerts and alarms.

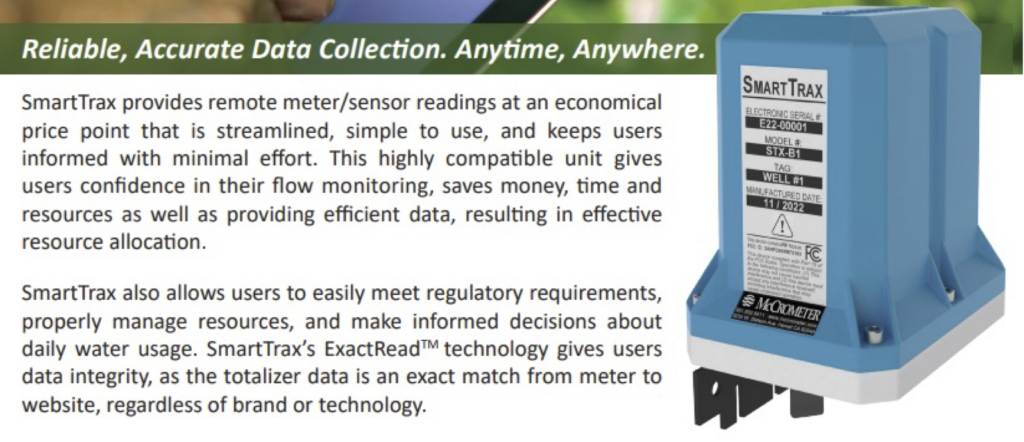

SmartTrax is McCrometer’s solution for the data management side of the equation. The meter can directly interface with SmartTrax utilizing our AMI output. The unit can be powered via lithium batteries or a solar panel with rechargeable batteries. This is a great low cost solution to your data management needs.

The Field Mag 3000 used for Basic Water Transfer is available with AC, DC, or battery power. If powered by AC or DC power, the battery acts as a battery backup. The outputs available on the Field Mag 3000 are pulse, passive 4-20mA, and McCrometer’s SmartTrax Telemetry transmitter.

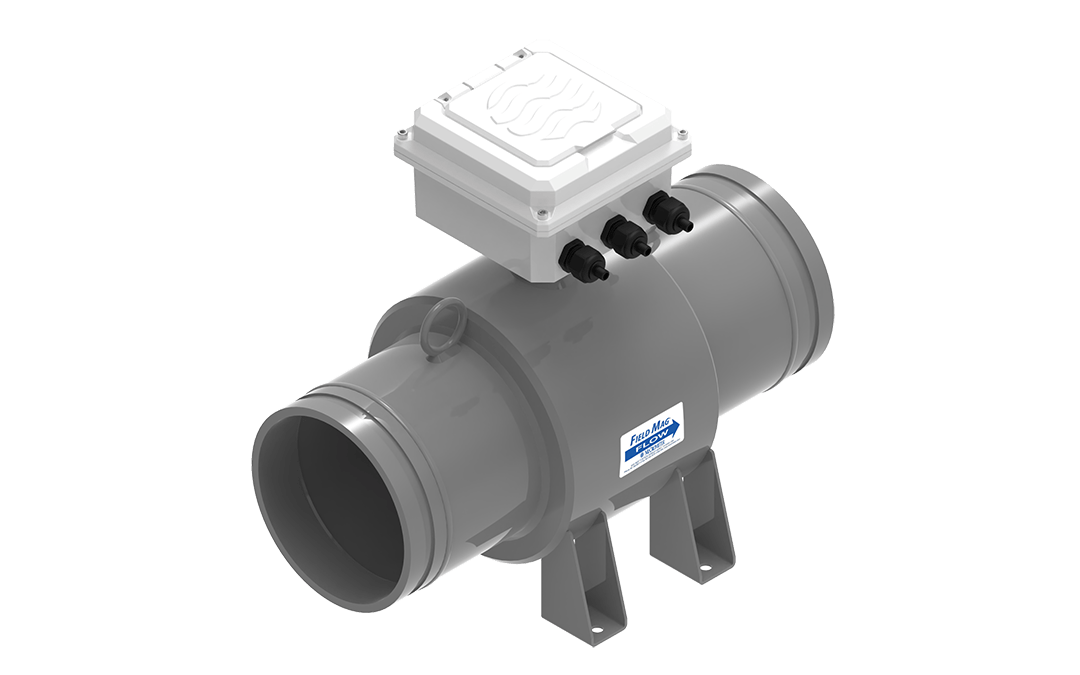

The Field Mag 5000 whose configuration is shown below, utilizes the ProComm electronics and requires AC or DC mains power and is the perfect solution to your Advanced Water Treatment needs.

FM510-VSM000D2

- FM5– ProComm electronics

- 10– 10” meter

- V– Victaulic “Grooved End Connection”

- S– Stainless Steel Electrodes

- M– Meter Mounted Electronics

- 000– No Cable provided

- D– DC Power option 12-36VDC

- 2– Modbus + two 4-20mA, two pulse outputs

For additional information about this product series, reach out to your authorized flow meter representative, your McCrometer Regional Sales Manager, or directly to the factory.

Related Posts

Featured Posts

McCrometer, Inc. Announces Redesign of FlowComTM Digital Register

FOR IMMEDIATE RELEASE: September 3rd, 2024Contact: Aimee Davis, Vertical Marketing Manager, Agriculture McCrometer, Inc.AimeeD@mccrometer.com Hemet, Calif. – McCrometer, Inc., a globally recognized flow meter manufacturer, today announced the launch of their...

4 Reasons to Invest in a Meter Repair Program

New is always better, right? Not exactly. New can be expensive, unnecessary, and harder to get company approval for purchase. So when your flow meter needs maintenance, upgrades, or just a good cleaning, there’s no need to start shopping for a replacement. Invest in...

Get into the Groove: McCrometer’s Grooved-End Mag Meter

We’ll share the big news upfront! McCrometer’s integrated grooved-end mag meter is the only version on the market, and it’s revolutionary for a reason. Engineered to meet customer demand, this meter launched in January 2024 and is available for order now. This...

Request More Information