Produced Water and Blending Flow Meter Use Case

Chemical Composition – As one can imagine, water that has been recently separated from oil and sand in a separator will contain more than just pure water; after all the water is not purified at this point. One disadvantage of the compounds included in the water is that they can be very corrosive. At least in the Permian Basin, experience has proved that Hastelloy electrodes fare much better than stainless steel electrodes due to the chemicals found in the water source. The composition varies from shale play to shale play but one other facet is always consistent, produced water is chemically closer to the chemistry of the shale formation therefore works more efficiently with the chemicals used for fracking. Produced water is much more effective than fresh water and allows for better assimilation of the frac fluids into the rock. Another benefit to using produced water is cost savings. Not only do you not have to remediate the produced water and pay to dispose of it through a salt water disposal facility, you can use it as a substitute for clean water and save money by not purchasing as much fresh water as was done previously. To be clear, you would not use 100% produced water as it has to be slightly remediated to be reinjected through the frac. A key component to measure is the total dissolved solids which is typically used to inform the blending process.

Blending – Produced water blending is a simple process. A fresh water line is paired with a produced water line in a “Y” configuration. The output is a blend of fresh and produced water. Water chemistry is tested in a continuous process and the valves supplying both fresh and produced water are modulated to provide the desired result.

Temperature – Another component to consider when metering produced water is temperature. Not only does the water contain a bunch of nasty chemicals and compounds, it can also be quite hot depending on where the measurement point is placed. McCrometer upgraded their Ultraliner so that instead of a 140F limit, with the new gray colored epoxy, the Field Mag series can withstand 200F. This will certainly help in those difficult locations.

Pressure – Another component that McCrometer took into consideration when developing our Field Mag series of products is pressure. Some of these locations are using higher pressures. We’ve increased our pressure capacity on the Grooved End versions of the Field Mag to meet ANSI #150 standards. Additionally in our flanged version of the Field Mag, we can get to ANSI #300 from 2” and 3”- 24”.

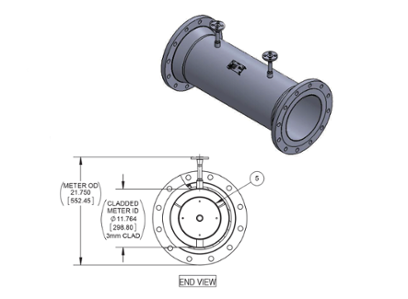

Produced Water, while a bit more complicated than a standard fresh water measurement, is not an impossible measurement point. We have two versions of our Field Mag Series that are most often used for Produced Water

The Victaulic Produced Water Meter typically uses the following configuration and is based on a 10” meter since this is the most popular:

FM510-VHM000D2

- FM5– ProComm electronics

- 10– 10” meter

- 2– ANSI #150 flange

- H– Stainless Steel Electrodes

- M– Meter Mounted Electronics

- 000– No Cable provided

- D– DC Power option 12-36VDC

- 2– Modbus + two 4-20mA, two pulse outputs

The Flanged Produced Water Meter typically uses the following configuration and is based on a 10” meter since this is the most popular:

FM510-2HM000D2

- FM5– ProComm electronics

- 10– 10” meter

- 2– ANSI #150 flange

- H– Stainless Steel Electrodes

- M– Meter Mounted Electronics

- 000– No Cable provided

- D– DC Power option 12-36VDC

- 2– Modbus + two 4-20mA, two pulse outputs

For additional information about this product series, reach out to your authorized flow meter representative, your McCrometer Regional Sales Manager, or directly to the factory.

Related Posts

Featured Posts

3 Reasons Why Budget-Focused Farmers Invest in Integrated Telemetry

Allocating budget to flow technology may seem unjustifiable when funds are tight; flow meters and their electronics may already be installed, giving no reason to replace or add additional units when the current solution is in fine working condition. However, flow...

Small Package, Big Impact: The Importance of Desiccant Cartridge Maintenance

You’ve likely seen a desiccant cartridge, in the form of the small silica gel packet accompanying food products, or the activated carbon packet at the top of pharmaceutical bottles. It’s also commonly used in electronics and near sensors, especially for...

Meeting BABA Compliance and Expanding Opportunities

Content Recorded and Published at WEFTEC in October 2024 In this episode of The Water Online Show: On Location, (now former) McCrometer President Pete Oveson dives into the company's story and recent developments shaping its future. He begins with an overview of...

Request More Information