4 Reasons to Invest in a Meter Repair Program

The advantages of the MRP are in your favor. Read how.

A New Meter without the New Meter Price Tag

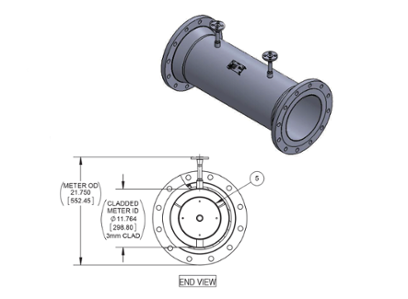

The MRP takes your Mc®Propeller, Water Specialties®, FPI Mag®, or Ultra Mag® and refurbishes it like new. While the process varies by technology and meter components, the basic procedure is:

- Parts replacement: for propeller meters, this can include a new propeller assembly, miter gear frame assembly, vertical shaft collar and bearing, o-rings, meter gears, and more. For mag meters, which are absent of any moving parts, cables might be replaced as well as grounding rings.

- Routine cleaning: a variety of the prop meter components are inspected, cleaned, calibrated, and repaired if necessary, including but not limited to: gaskets, O rings, drive cables, registers, paint touch-ups. For mag meters, the meter body and electronics are cleaned, tested for performance, and epoxy or paint touched up.

- Recalibration: once parts are replaced, cleaned, inspected, and the entire meter is rebuilt, the meter is then recalibrated and the customer provided with a three-point flow test document for proof of performance. This is completed for both propeller and mag meters.

Each component of the meter is refurbished, replaced, or repaired to like-new working condition, providing customers with a measurement device that is, on average, 40% less than the typical expense of a brand-new flow meter. The MRP is a budget-friendly option that allows you to get the most out of your meter investment for even more years to come. It’s especially beneficial for flow meters serving tough applications, harsh environments, meters operating for 10+ years, have incurred slight damage (like a cracked electronics housing) or simply need a face lift.

The recently enhanced Meter Repair Program also benefits customers needing either a reduced or extensive level of meter service. The tiered model and pricing ensures customers are receiving the level of service that benefits their flow meter and application needs. For a full look at the service plans and pricing, visit the Meter Repair Program web page.

Fresh Meter Performance without New Project Specification

For customers who encounter difficulties getting buy-in from stakeholders to purchase new flow measurement equipment, the MRP is a different, and often more accessible, approach. There’s no need to specify a new meter – because it’s the same meter being refurbished and repaired. Under the Meter Repair Program, each meter is rebuilt with the latest design features of each component. There’s even the opportunity to upgrade the electronics or incorporate new elements, such as Smart Output™ or SmartTrax™ telemetry. McCrometer’s factory can convert mechanical registers to digital FlowCom registers or FlowConnect™. For mag meters, the ProComm Go™ can be swapped out for the ProComm™. The MRP gives your meter a new lease on life, for both the meter body as well as the electronics, without the need to specify a brand-new flow meter!

Peace of Mind, Guaranteed

Each flow meter under the MRP comes with a 1 year full-meter warranty endorsing the pristine condition of the product – because under the Meter Repair Program, your meter is just like new. Your meter is thoroughly inspected to ensure all parts, components, and electronics are in flawless working condition, discontinued parts are replaced with the updated version, and the meter is reassembled meticulously before being shipped back to the installation site.

Should the meter not perform to specification, or any of the parts cause problems down the line (or in your line!) you and your team can rest easy knowing that it’s covered under warranty. For extra peace of mind, as of May 2024, McCrometer has yet to have a flow meter return to the factory for unforeseen, warranty-covered maintenance following a routine MRP!

The Meter Repair Program is Green

Remanufacturing and meter repair is the most environmentally-friendly means of acquiring an updated, state-of-the-art measurement device. For companies and organizations striving to achieve a lower carbon footprint, contribute to more resource conservation, or support sustainable manufacturing practices, McCrometer’s Meter Repair Program upholds that paradigm.

At its core, McCrometer strives to provide customers with long term, quality flow measurement solutions that support project goals and tackle the most challenging flow applications. As a Veralto Water Quality company, our efforts support the joint mission of Safeguarding the World’s Most Vital Resources™, an objective that advocates for sustainability and conservation.

McCrometer’s manufacturing efforts focus on resource circularity and investing in quality, made in USA standard materials to produce long lasting flow meters that serve our customers’ flow applications for decades. The Meter Repair Program closes the product life cycle loop and supports optimal resource and material use.

Get Started with McCrometer’s Meter Repair Program

McCrometer’s MRP is now available for the Mc®Propeller, Water Specialties™, FPI Mag®, and Ultra Mag® flow meters, so it’s time to get started on your meter’s repair and reconditioning. Visit the MRP web page to learn more about the program and sign up. For additional resources and information about McCrometer’s other service and support offerings, visit our website or contact the factory for a quote.

Related Posts

Featured Posts

3 Reasons Why Budget-Focused Farmers Invest in Integrated Telemetry

Allocating budget to flow technology may seem unjustifiable when funds are tight; flow meters and their electronics may already be installed, giving no reason to replace or add additional units when the current solution is in fine working condition. However, flow...

Small Package, Big Impact: The Importance of Desiccant Cartridge Maintenance

You’ve likely seen a desiccant cartridge, in the form of the small silica gel packet accompanying food products, or the activated carbon packet at the top of pharmaceutical bottles. It’s also commonly used in electronics and near sensors, especially for...

Meeting BABA Compliance and Expanding Opportunities

Content Recorded and Published at WEFTEC in October 2024 In this episode of The Water Online Show: On Location, (now former) McCrometer President Pete Oveson dives into the company's story and recent developments shaping its future. He begins with an overview of...

Request More Information