High Flow vs. Low Flow: Only the Meter Knows

The center-pivots are in place, wells are drilled, water is flowing, and crops are growing. This is farming – but could farmers be doing more? Is the crop yield as profitable as it could be? Has the water table changed over the years? These are all questions that can impact a farming operation and the profitability of that farm.

Keep reading to find out if your farm could be saving money with one simple solution.

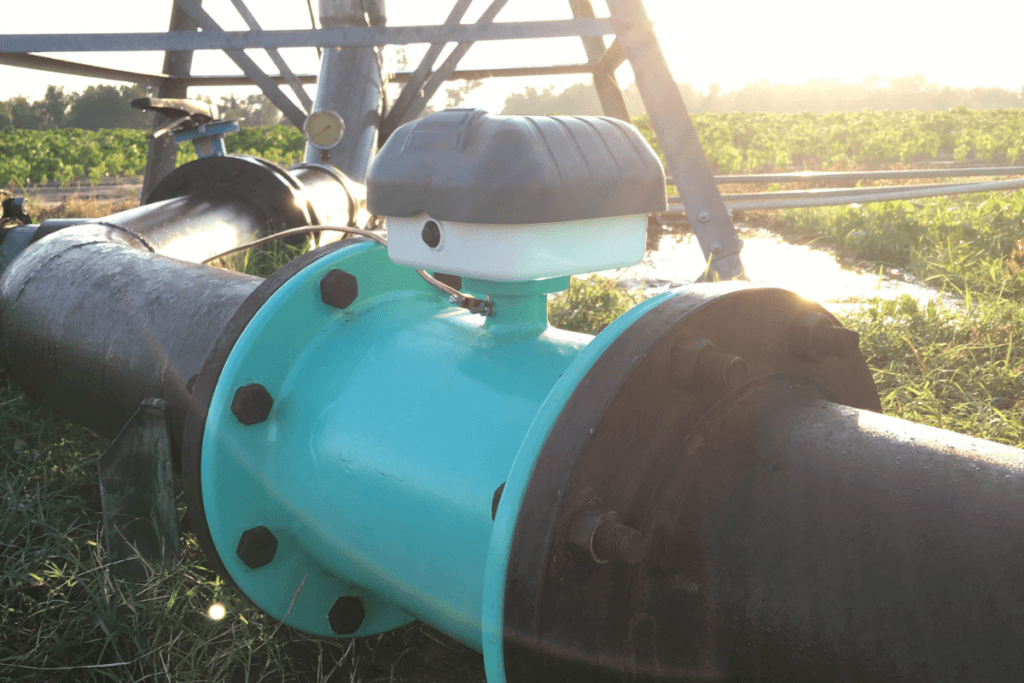

A Dura Mag installed in-field.

Water: The Source of Life

Farm to farm, there will be a thousand and one differences; from crop type to plot size, each farmer will have their preferences on equipment, process, and strategy. But there is one thing that every farmer from every continent will agree upon. And that is the crucial need for water. Without water, there is no farming, and there is no life. It is essential to realize that our world’s natural resources are being used every day without a constant source of replenishment. That is why farmers must know precisely how much water they are using, not only for personal profitability but also for our earth’s sustainability.

Flow: Know it & Adapt to it

When a farmer has data, he can make sound decisions that are thoroughly thought through and historically proven to work. Water usage is no different. Knowing the water’s flow rate on the farm is as crucial as knowing the upcoming weather conditions. Flow rates can vary from farm to farm and from well to well. High flow versus low flow can impact the crops, pivots, electrical bills, and much more, so knowing the flow rate is vital. Once a farmer knows their flow rates, they can quickly adapt to the changing conditions of their water supply.

High Flow vs. Low Flow

Why does this matter? Having a high flow may mean more access to water for that specific farm, meaning that there will be higher pressure running through the pipes, pumps, and meters. Having a low flow may signify a lack of water supply, making it even more important to know the water usage for those users.

For example, a Texas farm may have a low water supply, making the flow extraordinarily low. They could be pumping 300 gallons per minute (GPM) through a half-mile system. On the other hand, a farm in Georgia could run 3000 GPM in a half-mile system, giving them an extremely high flow.

The two farms from the example need varying irrigation methods due to their flow rate differences. And the only way to know the flow is through metering.

The Meters, the Data, and the Savings

McCrometer believes metering to be a proactive approach in monitoring our earth’s water supply. Many farmers may be apprehensive about installing a meter on their wells or pivots, but the truth is farmers should be more afraid of not having a meter. Meters can share so much insight into a farming operation, and the data obtained from these meters can help impact the bottom line dramatically. The question should not be, “should I install a meter” but rather “which meter is right for my operation and flow rates?”.

Two of the most popular meters used among farmers are the McPropeller meter and the Dura Mag™ meter. Both meters give farmers best-in-class accuracy rates of ±2% (Mc Propeller) and ±1% (Dura Mag).

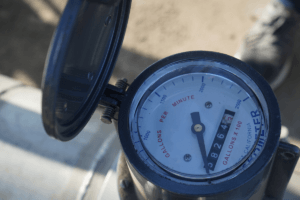

A closeup of a McPropeller mechanical dial face.

The Mc Propeller meter performs well in high flow applications. McCrometer can add an extra set of bearings on the meter to give additional stability and support for an improved lifetime. These meters can serve line sizes from 2″-96″, giving farmers flexibility. The epoxy-coated carbon or stainless-steel body comes pre-calibrated and ready for installation upon delivery. The pipe requirements of this meter include a minimum of 5 to 10 diameters upstream and 1 to 2 diameters downstream.

Dura Mag meters are a fantastic option for low-flow farmers. The line size variation allows for 4″ to 12″ diameter and only requires 2 diameters upstream and 1 diameter of downstream straight pipe. If there is a full pipe, McCrometer meters are there to measure.

*Pro Tip: When drilling a new well, ensure yourself enough room for a meter installation. A good 15 to 20 feet away from the pivot should allow enough room for a meter and other equipment inside the pipes!

Ask the Experts!

For any questions regarding flow rate, metering, or installations, reach out to us today!

Or, for a quick quote, click here!

Related Posts

Featured Posts

Get into the Groove: McCrometer’s Grooved-End Mag Meter

We’ll share the big news upfront! McCrometer’s integrated grooved-end mag meter is the only version on the market, and it’s revolutionary for a reason. Engineered to meet customer demand, this meter launched in January 2024 and is available for order now. This...

Produced Water and Blending Flow Meter Use Case

Produced Water is a byproduct of oil production. Whether it is a byproduct of flow back or the water component of the oil separation process, produced water can be a difficult measurement point but is a very important part of the process. Several parameters make it...

Get your Groove on Now: McCrometer’s Grooved-End Mag Meter Now Available

It is time to get your Groove On. McCrometer has released their innovative Electromagnetic Flow Meter with integrated Grooved End connections. Are you tired of bolting on extra flanges with Victaulic end connections welded to them? It is time consuming and makes an...

Request More Information