McMag 2000 vs. McMag 3000: What’s the Difference?

We’ll let you in on a secret – the difference is more than just a number! The names may be similar, but each meter has a unique construction and design, different product specs, and value-rich features that different customers favor.

The Mag Meter Tech Specs

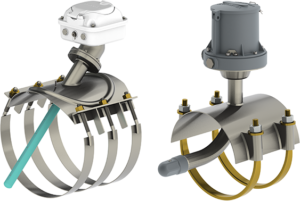

Despite the fact that both products are electromagnetic (mag) meters, they differ in construction. The Mc®Mag 3000’s sensor is similar to the FPI’s and contains more electrodes, and is more intrusive into the line. However, the tilted sensor placement allows the Mc®Mag 3000 to get a more accurate reading in the pipe, up to ± 1% with custom factory calibration. The saddle is the same design as McCrometer’s Water Specialties® propeller meter, featuring the three stainless steel U-bolts.

The Mc®Mag 3000 also offers a more feature-rich converter, offering pulse-out options like Sensus and Itron, as well as 4-20mA and option to connect up to two additional sensors. It’s ideal for system integration with popular municipal software like SCADA and is often used by irrigation and water districts in applications such as precision custody transfer.

Although both meters are saddle-style, the Mc®Mag 2000 uses the Mc®Propeller’s same saddle, allowing the Mc®Mag 2000 to be retrofittable for customers wanting to make the change to a “no moving parts” meter. Due to its retrofittable nature, the Mc®Mag 2000 uses the McPropeller’s elbow-shaped hardware and adds a dual-electrode sensor to the end via ethernet-style cable. The sensor sends out a more circular signal to achieve its ± 2% accuracy. The Mc®Mag 2000’s converter has a scrolling display showing both totalizer and flow rate on one screen and offers pulse-out options as well for system integration.

The McMag3000 and the McMag2000

Choosing One Mag Over the Other

Both the Mc®Mag 3000 and the Mc®Mag 2000 are great options for a variety of flow applications in municipal and agricultural industries, but there are certain instances where one is more ideal than the other.

For those needing more system integration and more precise accuracy, the Mc®Mag 3000 is ideal. Water and irrigation districts choose the 3000 because they require smart output and compatibility with Sensus or Itron, likely due to an existing system they have in place. Municipal water districts can set up relay stations in neighborhoods to connect meter points to their main hub and utilize pulse-outs for their monitoring needs.

In agriculture, communication hubs are typically more spread out, and a 4-20mA current signal is often more desirable. If growers already have a detailed and integrated irrigation system in place, the Mc®Mag 3000 may be the right choice to provide the level of accuracy needed, especially if frequent water usage reporting is required or the grower has a water allocation.

If ± 2% accuracy is sufficient and an irrigator would like to retrofit their McPropeller, the Mc®Mag 2000 is the winner. The interface is simpler and customizable, as the user can change units and access the data on the converter through a convenient micro USB port.

The desire to refrain from adding to the existing pipeline may be a factor that sways the decision between the meters, as the McMag2000 has a 5:2 straight run requirement and the Mc®Mag 3000 has a 3:1 requirement, which may mean the difference in having to re-pipe your system to achieve the straight-run requirements. In addition, the Mc®Mag 2000 has a grounding plate built into the side of the converter, and requires no additional grounding, whereas the Mc®Mag 3000 requires grounding rings to be installed to a stable source in order to cut down on surrounding electrical noise.

Choosing the Right Mag Meter for Your Needs

Ultimately, choosing between the McMag2000 and the Mc®Mag 3000 is a matter of your specific application and your functionality needs. McCrometer flow meters are great tools to help you manage your resources and provide you with the flow measurement data you need to make informed decisions about your day to day operations.

We recommend watching our YouTube videos to become more informed about installation and meter functionality, and downloading each product’s specification sheets and manuals from our website to understand more of the technical details. And of course, the flow professionals at the factory are always available to contact with questions or a quote when you’re ready to start your next flow project.

Related Posts

Featured Posts

3 Reasons Why Budget-Focused Farmers Invest in Integrated Telemetry

Allocating budget to flow technology may seem unjustifiable when funds are tight; flow meters and their electronics may already be installed, giving no reason to replace or add additional units when the current solution is in fine working condition. However, flow...

Small Package, Big Impact: The Importance of Desiccant Cartridge Maintenance

You’ve likely seen a desiccant cartridge, in the form of the small silica gel packet accompanying food products, or the activated carbon packet at the top of pharmaceutical bottles. It’s also commonly used in electronics and near sensors, especially for...

Meeting BABA Compliance and Expanding Opportunities

Content Recorded and Published at WEFTEC in October 2024 In this episode of The Water Online Show: On Location, (now former) McCrometer President Pete Oveson dives into the company's story and recent developments shaping its future. He begins with an overview of...

Request More Information