7 Factors to Consider when Purchasing and Installing your McPropeller

McCrometer’s classic McPropeller, the original propeller meter introduced to the agriculture market, has been the top choice of the American farmer since 1955. In addition to a reputation for reliability, irrigators appreciate this durable piece of equipment that is easy to install, service, and maintain for 20+ years.

That being said, it is still a sophisticated measurement device with intricacies that need to be considered during installation, especially in regard to the application and the surrounding environment. It sounds overwhelming, but it’s simple – here’s the top 7 factors to consider when purchasing and installing your McPropeller.

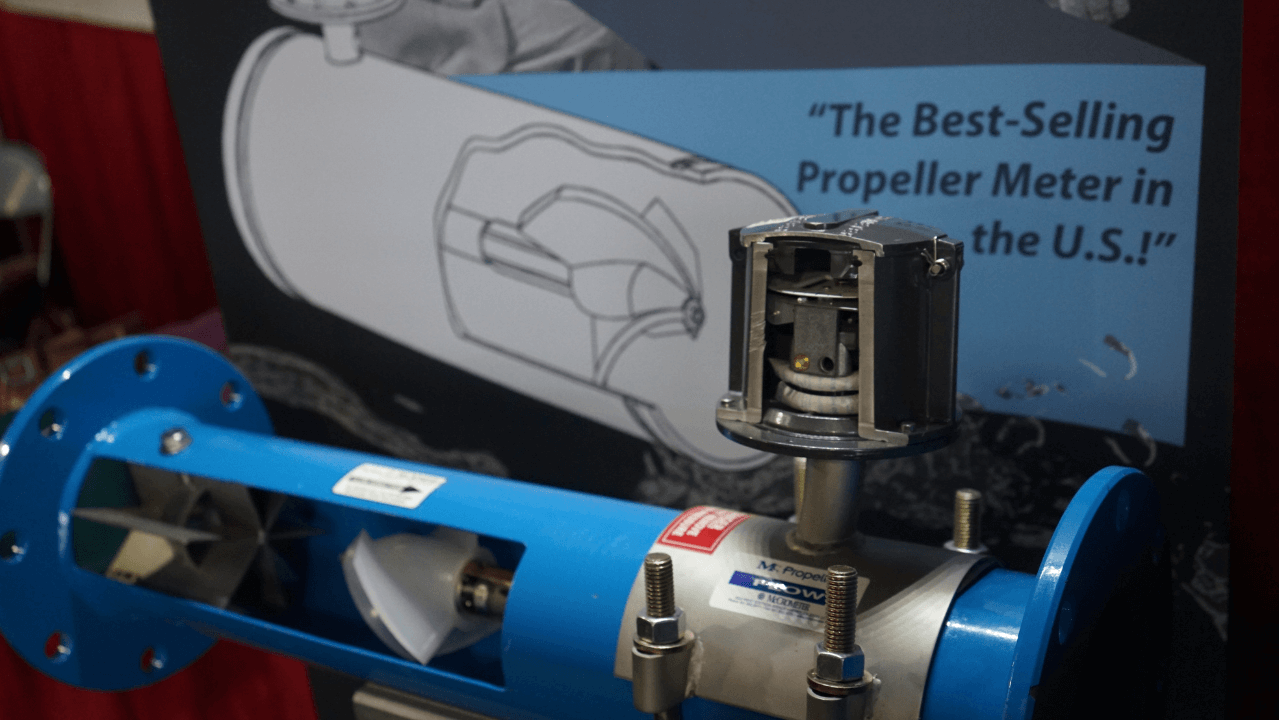

A demonstration of the McPropeller, showing the interior mechanics and accompanying flow straightener.

1. Consider the pipe material

In addition to knowing your pipe’s outside and inside diameter (needed for ordering and calibrating your flow meter) you should know how the pipe material can influence the meter model and/or configuration. If a saddle meter is installed on an aluminum pipe, you need to ensure that the U-bolts aren’t overtightened, which might crush the pipe and prevent a good gasket seal. This may cause leakage and faulty meter readings.

You should also ensure that the pipe material is the same when you install your meter as it was when you specified the meter, as the outside diameter (OD) and the inside diameter (ID) of your pipe are variables needed for accurate calibration.

Helpful tip: the McCrometer team has specifications on hand for popular classes of pipeline materials that can assist with OD/ID measurement during the ordering process.

2. Consider any pipeline obstructions

A meter’s performance depends on proximity to its surroundings. Are there any obstructions or disturbances such as pumps, valves, elbows, or tees nearby? It is critical to know how much upstream run you have and the distance from obstructions like pumps and check valves that may take up some of that straight run. Any one of these flow disturbers could necessitate a flow straightener to reduce the required straight run.

Additionally, if an irrigation well has a chemigation unit, the meter should be installed upstream of the chemigation unit, so the injected chemicals don’t corrode the mechanical components of the propeller meter.

Helpful tip: Do you need the detailed specifications for where to install your McPropeller? Visit the IOM manual!

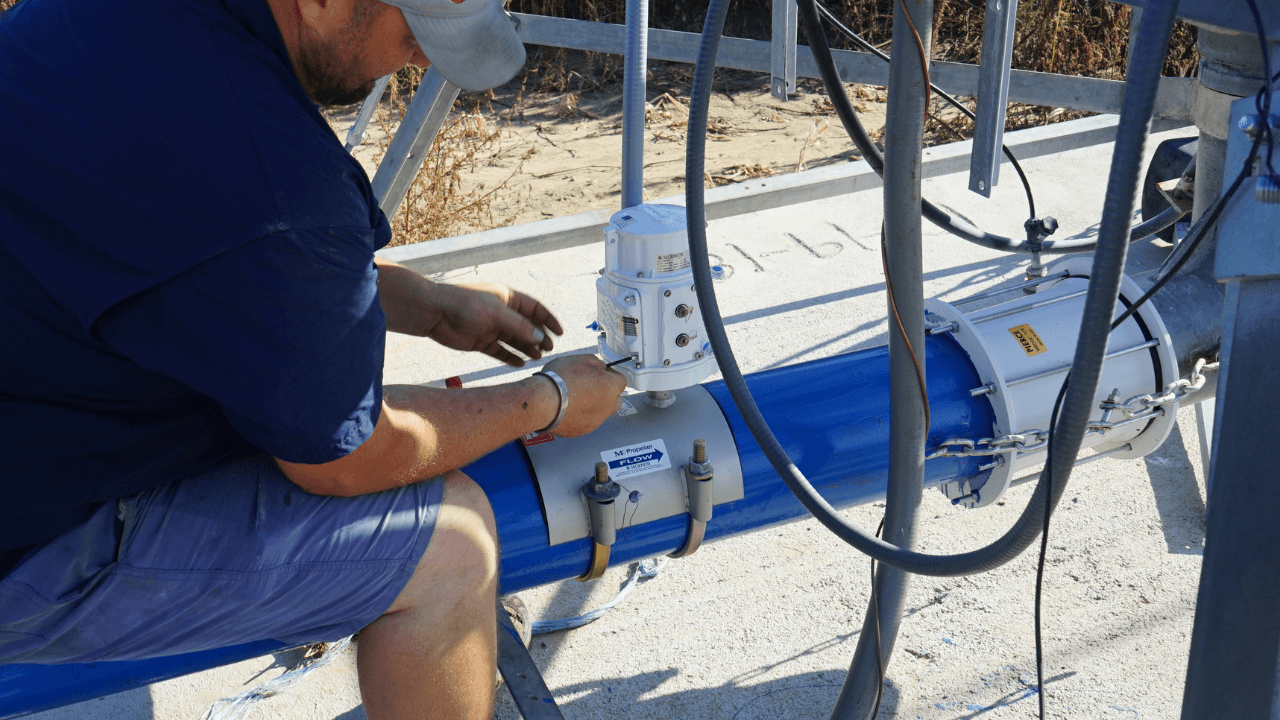

A saddle-style McPropeller with FlowConnect™ unit being installed on a center pivot.

3. Consider your output needs

When ordering and installing a McPropeller that emits a signal, the installation location is important. If you have a base station receiving signals to control pivots and want to integrate a meter signal (via pulse output or 4-20mA, for example) you need to ensure you have the right transmitter, digital register, or telemetry unit. The meter should be installed where the unit can be hardwired, for optimum performance. For pulse cables, the standard length is 25 feet, so the unit should be installed close enough to wire into your control panel. For cellular signal output, the recommendation is to install on higher elevations such as a hill, rather than a valley, to obtain the best signal. If you plan to take a signal off the meter to integrate into a larger system, it’s recommended to install the meter within a certain distance of the pivot panel.

Helpful tip: Cables carrying the signal from the meter to the irrigation system should be placed in a conduit to protect from rodents, mechanical damage, or other threats that may cause damage.

4. Consider the meter orientation

When a flow meter is ordered, the default orientation is horizontal. The McPropeller can be installed vertically, but this needs to be stated during the ordering process as the meter needs to be calibrated for a vertical installation. The mechanical register version of the McPropeller contains a magnet necessitating a calibration for the rate of flow needle. If a horizontal McPropeller is ordered, it must be installed on top of the pipe to maintain the integrity of the magnetic drive and the accurate flow readings.

Helpful tip: A digital register on the McPropeller does not require a special calibration based on vertical or horizontal installation and it has built-in signal outputs.

5. Consider any metering regulations

Many meter-regulated states specify meter installation (in addition to other measurement factors such as technology and manufacturer models). Some natural resource districts (NRDs) or departments of water resources (DWRs) specify a flow meter to be installed as close to the well as possible, to measure water discharge. For simple irrigation systems measuring one well source to a single pivot of irrigation unit, the installation point isn’t as crucial. However, for operations involving multiple wells pumping to a single pivot, or a single well pumping to multiple pivots, many regulators require meters at the delivery points to measure all usage.

Helpful tip: always check with your local and state regulators to ensure that your meters are adhering to all installation parameters. Your local dealer and McCrometer Regional Sales Manager are also valuable resources.

6. Consider the water quality of your flow

Whether or not your flow project involves pumping surface water vs. groundwater will help decide what flow meter works for your application. For applications pumping water with debris, you may need to install a grate to help filter out organic matter and prevent the propeller from becoming clogged. Additionally, it’s important to understand that while the McPropeller is a favorite of the farmer, it’s not the only option, and for good reason! Other metering technologies, such as the electromagnetic flow meter, are better suited for certain agriculture and irrigation applications (check out our blog on the subject). Often, a silty or clay-based surface water source necessitates a mag meter, as in the case for our customer, Sidney Water Users Irrigation District (read their mag meter success story here!)

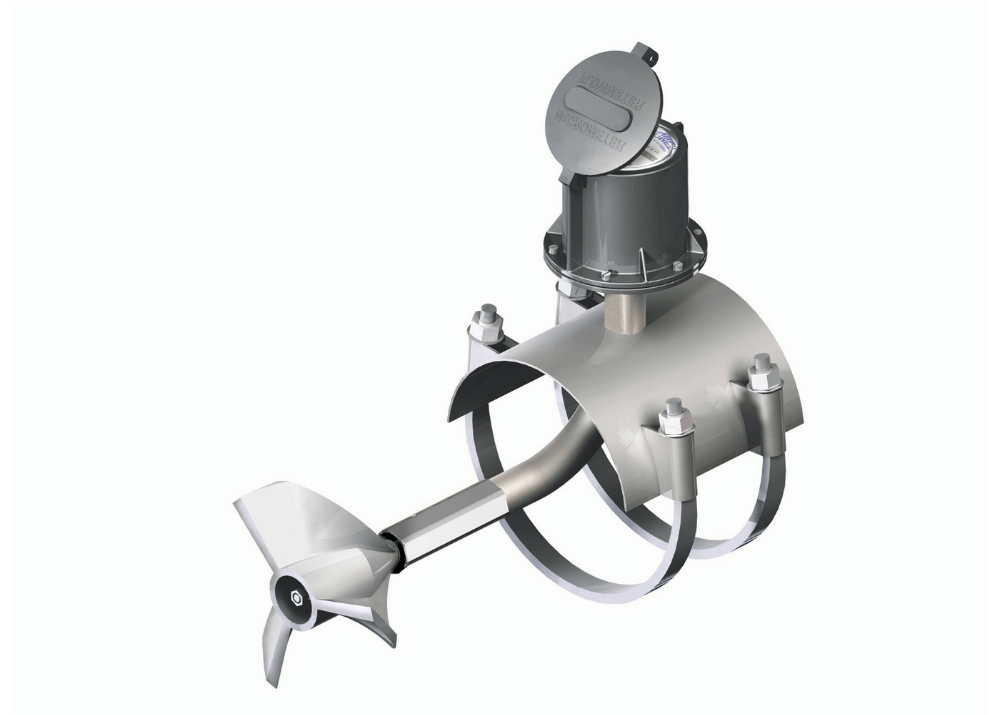

Helpful tip: the SW model of the McPropeller is a reverse-oriented propeller configuration that sheds debris!

The MO300SW reverse-style McPropeller.

7. Consider the working pressure and flow rate

Know the PSI of your flow project, as that will help ensure your meter’s success. Many of our McPropeller configurations have a maximum PSI of 150, but if your project’s flow rate is higher, that will limit the model selection. Additionally, if your project is lower pressure, the McPropeller has certain models that go down to 75PSI, such as the ML100.

Higher flow rates necessitate a marathon bearing to increase the life of the mechanics, and ultimately prevent early maintenance and replacement parts. If your flow rate is lower than 50 gallons per minute (GPM), you likely need another flow technology, such as a mag meter, or your pipe may need to be smaller to increase your flow rate.

Helpful tip: Mechanical propeller meters operating at the lower end of the standard flow range may not need the marathon bearing. Talk to your local dealer about which McPropeller configuration is best for your flow rate and installation needs!

Related Posts

Featured Posts

Small Package, Big Impact: The Importance of Desiccant Cartridge Maintenance

You’ve likely seen a desiccant cartridge, in the form of the small silica gel packet accompanying food products, or the activated carbon packet at the top of pharmaceutical bottles. It’s also commonly used in electronics and near sensors, especially for...

Choosing the Right Non-Contact Flow Meters: A Quick Dive into Radar and Laser Technologies

When measuring open channel flow wastewater and stormwater, non-contact flow technology is the ideal method, able to provide an accurate velocity and flow rate. Especially in the wet weather season, non-contact flow technology greatly benefits open channel...

Meeting BABA Compliance and Expanding Opportunities

Content Recorded and Published at WEFTEC in October 2024 In this episode of The Water Online Show: On Location, (now former) McCrometer President Pete Oveson dives into the company's story and recent developments shaping its future. He begins with an overview of...

Request More Information