Water Monitoring in Montana: One Irrigation District’s Success with the McMag2000

This article was originally published in the July/August 2021 issue of Irrigation Leader.

Irrigators who have been metering for some time often have a preferred measurement technology, opting to stick with a certain style of flow monitoring device year over year. However, when flow monitoring requirements and preferences change over time, branching out to adapt new technology can bring significant advantages to everyday operations. This evolution of flow monitoring needs is just what Sidney Water Users Irrigation District (SWUID) experienced as they implemented various McCrometer flow meters – and as they became an early adopter of McCrometer’s new Mc®Mag 2000™.

To learn more about their experience with the Mc®Mag 2000 and the overall McCrometer product suite, we spoke to Raymond Bell, president of the board of directors for SWUID, about the district’s flow projects.

From Open Ditches to Pipeline Operations

Although pumping water since the 1940s, the SWUID only recently began metering 12-14 years or so ago. They’ve found great success in applying for and being awarded state grant money to advance their pipeline operations, including investing in flow metering projects. In 2006, SWUID began using McCrometer’s Mc®Propeller meters, the original product McCrometer developed for the agricultural market more than 65 years ago. SWUID installed multiple 27” McPropeller meters off pump applications and 12” meters at turnouts for field applications.

Installed in a pit, propeller meter digital output eliminates the need to physically check the meter to monitor flow.

Measuring the water from multiple pumps to various pipelines became their main flow project application, and as SWUID became familiar with their monitoring operations, the district soon desired the ability to monitor in real-time, and through digital means. This led SWUID to seek a metering solution from McCrometer that provided them with digital output options.

From Propeller Meters to Mags

Electromagnetic (mag) meters are generally pricier than propeller meters, but the “no moving parts” design as well as potential value-added features are often a draw for irrigators. In 2016, the district purchased several 12” Mc®Mag 3000™ flow meters and utilized pulse output to receive constant flow data to cell phones. Rather than physically inspecting propeller meters’ dial faces for totalizer and flow rate information, the Mc®Mag 3000’s digital output capabilities allow for remote meter data monitoring.

A surface-level McMag3000 installed by Sidney Water Users Irrigation District.

The Mc®Mag 3000 offers a range of features, including datalogging, DC power option,

± 1% accuracy with factory calibration, and more; the range of features and available higher accuracy cause this product to be a significantly higher price than the McPropeller, a price tag that affected the quantity that could be purchased with state grant funds.

When McCrometer unveiled the Mc®Mag 2000 flow meter in 2020, a product similar in design to the 3000 model but offering fewer features for a more economical price tag, SWUID was interested and approached McCrometer about adopting the newly launched mag meter.

Custom to Customer

The similarity in price between McPropeller and Mc®Mag 2000 was particularly appealing to SWUID, but there were many other components about the mag meter that met the district’s metering needs. The pulse-output capability allowed the district to maintain their remote monitoring, and the easy in-field maintenance kits gave the district peace-of-mind for future meter upkeep.

“Sidney Water draws very silty, debris-filled water from the Yellowstone River,” explains Bell. “That kind of flow media can be very corrosive to propeller meters and their bearings. I’ve rebuilt a lot of the tube-style propeller meters myself. Implementing mag meters has greatly reduced our need for maintenance.”

SWUID needed an economical meter that would handle the velocity of the water at the installation site. The metering project was measuring flow off floater pumps, pushing water uphill in multiple pipelines at 12” and 16” diameters at an average of 5000 gallons a minute.

Although the newly launched Mc®Mag 2000 was intended for line sizes 4” – 12”, the design engineers in McCrometer’s Research and Development Department knew the meter could be customized to meet Sidney Water’s needs.

Since installing his initial 12” and 16” Mc®Mag 2000 meters, Bell reports satisfactory performance – and has placed an order for 6 more Mc®Mag 2000’s for upcoming turnout application flow projects.

Due to the demand received from customers like SWUID since the Mc®Mag 2000’s launch in February 2020, McCrometer will be extending the Mc®Mag 2000’s line size offerings to cover 4” – 16”. These additional line sizes will be available on the Mc®Mag 2000 price list Summer 2021.

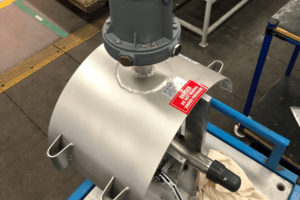

A custom line-size McMag2000 at the McCrometer factory, ready for shipment.

Flow Meters for Project Performance

Customers with unique flow projects like Sidney Water Users Irrigation District and President Raymond Bell allow McCrometer a better understanding of customer needs and potential future product improvements. Ongoing close customer relationships also allow McCrometer’s engineers challenging, yet rewarding, customization projects as well.

For more information about the Mc®Mag 2000 or to receive a quote on your upcoming flow project, visit www.mccrometer.com/ag

Related Posts

Featured Posts

Small Package, Big Impact: The Importance of Desiccant Cartridge Maintenance

You’ve likely seen a desiccant cartridge, in the form of the small silica gel packet accompanying food products, or the activated carbon packet at the top of pharmaceutical bottles. It’s also commonly used in electronics and near sensors, especially for...

Choosing the Right Non-Contact Flow Meters: A Quick Dive into Radar and Laser Technologies

When measuring open channel flow wastewater and stormwater, non-contact flow technology is the ideal method, able to provide an accurate velocity and flow rate. Especially in the wet weather season, non-contact flow technology greatly benefits open channel...

Meeting BABA Compliance and Expanding Opportunities

Content Recorded and Published at WEFTEC in October 2024 In this episode of The Water Online Show: On Location, (now former) McCrometer President Pete Oveson dives into the company's story and recent developments shaping its future. He begins with an overview of...

Request More Information