Small Package, Big Impact: The Importance of Desiccant Cartridge Maintenance

You’ve likely seen a desiccant cartridge, in the form of the small silica gel packet accompanying food products, or the activated carbon packet at the top of pharmaceutical bottles. It’s also commonly used in electronics and near sensors, especially for instrumentation in humid environments or exposed to the elements. Electronics designed for the water and wastewater industry are certainly both, in this case.

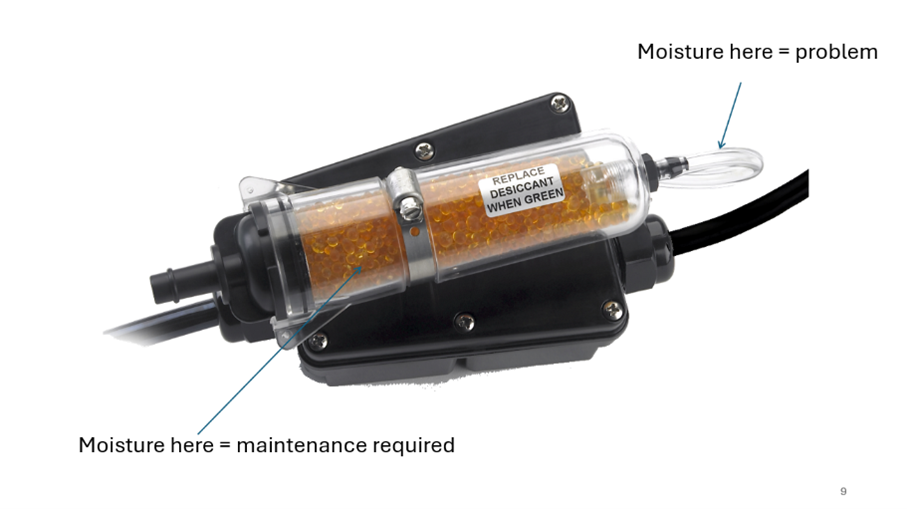

An image of a desiccant cartridge featured on some open channel flow devices.

Often overlooked, the small, nondescript desiccant cartridge is an important component in maintaining the performance and operation of electronics associated with flow measurement instrumentation, much of which is submerged within water or wastewater flow (or close to it).

But can that tiny dehumidifying packet truly have such a profound impact on the condition and performance of flow meter electronics and sensors? When utility managers and technicians rely on real-time, accurate flow data to maintain compliance, make informed decisions about daily operations, and potentially bill for water usage, fouled electronics have significant consequences.

Here’s what you need to know about that tiny packet and the enormous role it plays in your pipeline network.

Where You’ll Find a Desiccant Cartridge

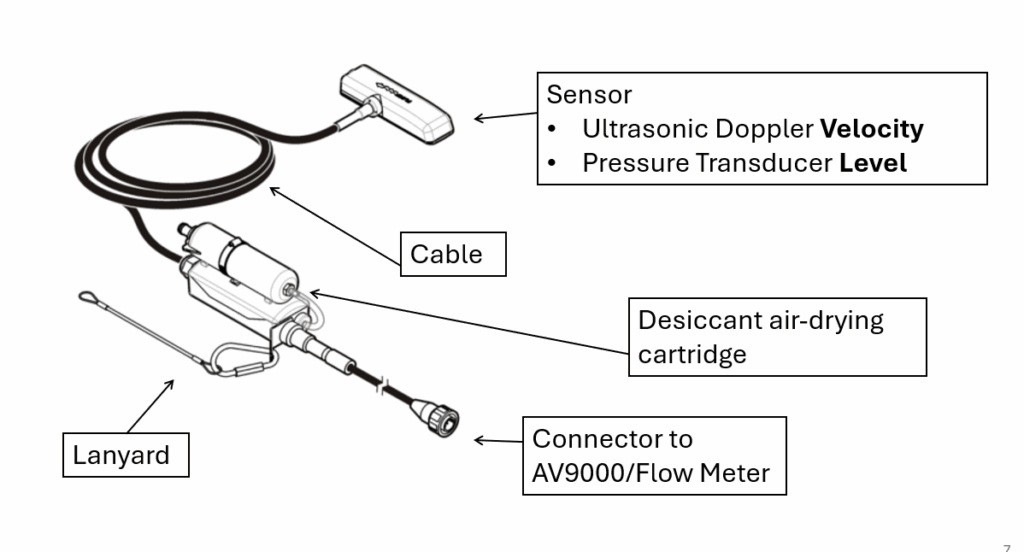

Flow instrumentation often contains a desiccant cartridge, or drying agent, within the electronics to remove any moisture that may have entered the unit during the manufacturing process. Additionally, this safeguard is in place to protect the unit when the customer replaces the batteries or opens the unit for maintenance purposes.

For open channel flow instrumentation such as level sensors, bubblers, or flow loggers, the desiccant cartridge is in-line with the vent tube. The vent tube allows the pressure transducer to isolate the pressure imparted by the water and negates the pressure contributed by atmosphere.

Without a free-flowing tube, the pressure transducer would see the pressure from the water depth and the weight of atmosphere. Atmospheric pressure changes with the weather; note that your local weatherperson says the pressure is rising or falling, and this is what is being referred to. In the case of a submerged area velocity sensor, a pressure transducer in the sensor converts the pressure the water places on the transduce of the water to a level measurement.

A desiccant cartridge attached to the cable and in-line with the vent is located near the flow logger and is positioned vertically with the end cap pointed down, so the atmospheric pressure reference is protected from moisture entrapment.

A diagram identifying the desiccant cartridge on the FLO-DAR® Area Velocity sensor

The Important Role of a Desiccant Cartridge

Put simply, a desiccant or drying agent ensures proper operation of the flow instrumentation. If the desiccant isn’t included, or is not properly maintained, moisture will alter the integrity of the flow and level readings.

In open channel applications such as wastewater or stormwater channels, high humidity and surcharge are inevitable, threatening flow and level measurement equipment. Should condensing moisture intrude and block the reference air tube, the level transducer will produce readings that drift from the device’s usual accuracy.

In addition to fouling, a depleted desiccant is the most common cause of level drift. Inaccurate, untrustworthy flow and sensor data will prevent wastewater professionals from making informed decisions about their collection system.

Desiccant Cartridge Best Practices

Each desiccant cartridge will need to be refilled at some point during the lifespan of the flow instrument, but the frequency will depend upon the flow application, location, seasonality, and surcharges.

- Flow application: If the installation is in a humid, contained location such as a manhole measuring wastewater flows, technicians may find that the desiccant requires replacing more frequently.

- Location and climate: Certain environments are more humid or arid than others. Flow applications in Arizona, for instance, may require less frequent cartridge replacement than applications in humid subtropical environments, especially if exposed to the elements rather than contained within a manhole.

- Seasonality: Technicians and operators may find that desiccant cartridges need more frequent replacing during the rainy season or during months with higher humidity levels.

- Surcharges: After wet weather events, a site visit is suggested to ensure proper functionality and performance of the flow devices is maintained, which may include desiccant replacement. This is especially important when surcharges have occurred at the installation site.

A photo of McCrometer’s FLO-DAR unit prior to installation, showcasing the orange desiccant cartridge near the unit. Photo courtesy of Oratech Controls, Inc.

Wastewater professionals who have numerous installation sites to maintain may find it difficult to visit each device frequently enough to sufficiently inspect the desiccant cartridge for necessary replacement.

Flow and level devices don’t contain alarms to notify users when the desiccant needs replacing and relies wholly on visual inspection to determine if maintenance is required. Technicians can double up on desiccant cartridges and daisy chain them together to safeguard their device for longer periods of time before scheduling routine maintenance.

However, best practices state that users should visually inspect the desiccant cartridge during each site visit and develop a unique maintenance schedule based on the needs of that installation site and the instrumentation installed.

While installing multiple desiccant cartridges is an added level of protection, it doesn’t eliminate the need for manual inspection and a dedicated maintenance schedule. Should technicians and operators fail to maintain their flow devices’ desiccant cartridges and withhold site visits, their indication for needed maintenance would be in the form of level readings beginning to drift.

With enough time, irreversible damage to the sensor would occur, causing a complete loss of real-time, accurate data, plus the cost to replace and install new flow instrumentation.

A Program to Make it Easier

Water and wastewater professionals often have an overwhelming pipeline network and a bevy of instrumentation to maintain. Visiting each installation site can take time away from other important, higher priority tasks, especially for a smaller municipality or one with limited ‘boots-on-the-ground’ personnel. As a flow instrumentation manufacturer as well as a flow service provider, we’ve witnessed this challenge within the industry.

A program exists to assist water and wastewater professionals with ongoing maintenance of their flow instrumentation, specifically for McCrometer’s FLO-DAR Area Velocity Sensor. This comprehensive service repair program is designed to keep flow monitoring equipment operating at peak performance, whether a unit requires routine maintenance or a complete repair.

In addition to sensor diagnostics, verification of measurement readings, and instrument cleaning, this service includes replacement of the unit’s desiccant cartridges to protect against moisture damage and ultimately extending the lifespan of the device.

For more information about this service, please visit our website at www.mccrometer.com

Key Insights

A dehumidifying cartridge or drying agent, as insignificant as it seems compared to the essential role of a level sensor or flow meter, contributes substantially to accurate, repeatable flow data. Even one droplet of water can interfere with the performance of flow and sensor equipment, producing erroneous readings. The difference between 4” and 4.5” of water doesn’t seem significant, but when moving at a high velocity, it’s a sizeable amount of water not being properly accounted for by flow devices.

If you want your instrumentation to perform to manufacturer’s specifications, proper maintenance is essential – either self-performed or contracted to the manufacturer or an authorized representative.

Author

Jim Caruso is the Business Development Manager for Hach’s Flow Solutions by McCrometer and has nearly 30 years of experience with flow and sampling instrumentation in both the municipal and private sector. Considered an expert in flow monitoring technology and automatic sampling, his subject matter expertise includes level and velocity measurement technologies.

Email: james.caruso@mccrometer.com

LinkedIn: Jim Caruso – Sales Business Development Manager – McCrometer, Inc. | LinkedIn

Related Posts

Request More Information