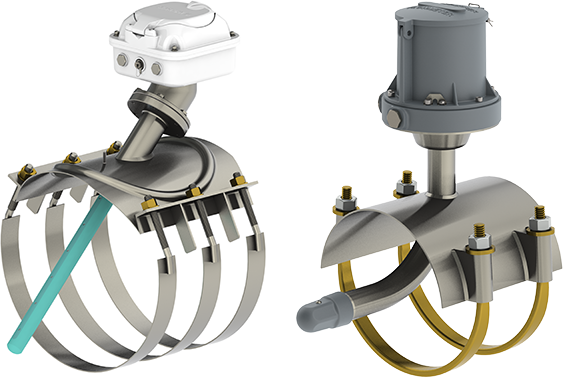

McCrometer offers four insertion-style electromagnetic (mag) meters, which have similar designs and product names. If you’re interested in an insertion mag meter, or are comparing them to traditional full-bore mag meters, here’s what you need to know in order to...