Choosing the Right Non-Contact Flow Meters: A Quick Dive into Radar and Laser Technologies

When measuring open channel flow wastewater and stormwater, non-contact flow technology is the ideal method, able to provide an accurate velocity and flow rate. Especially in the wet weather season, non-contact flow technology greatly benefits open channel applications, where submerged probe sensors or propeller meters may struggle to provide accurate readings due to debris in flow and the varying water levels. Older “primary device” technologies such as flumes and weirs can be monitored using a non-contact level sensor, but they require frequent maintenance, lest their accuracy be impaired by sediment build-up or accumulation of debris. Ideally, one should clean flumes and weirs at the start of every season and after any significant storm.

This is why non-contact flow measurement technologies, such as radar and laser, are often used for wastewater applications. Their lower maintenance requirements confer a significant operational advantage in terms of staffing and cost. Although similar in technology, each has specific strengths and weaknesses that depend greatly on the application, environmental factors, and required specifications for the flow project.

Principles of Operation

Radar flow meters emit high-frequency electromagnetic waves at microwave frequencies aimed at the stream of flow, bouncing off irregularities at the air-water interface and returning to the device. A frequency differential occurs due to Doppler shift and this shift is used to calculate the velocity of flow. A simultaneous level measurement is used to determine the cross-sectional area, and this is combined with the velocity measurement to determine the volumetric flow rate.

It is a common misconception that radar flow meters require particulate matter to provide reflective sites. In reality, radar sensors can measure completely clean water, provided that some minor degree of surface roughness is present. Sewage and storm water collection systems typically have design velocities high enough to ensure turbulent flow and this turbulence usually ensures sufficient surface roughness.

Laser flow meters emit a laser beam which penetrates below the flow surface, where particles within the flow reflect the laser light, producing a Doppler shift proportional to the particle velocity. Under most conditions, this particle velocity equals the flow velocity. Just as with radar instruments, an associated level measurement is used to calculate the volumetric flow rate.

Technology Benefits

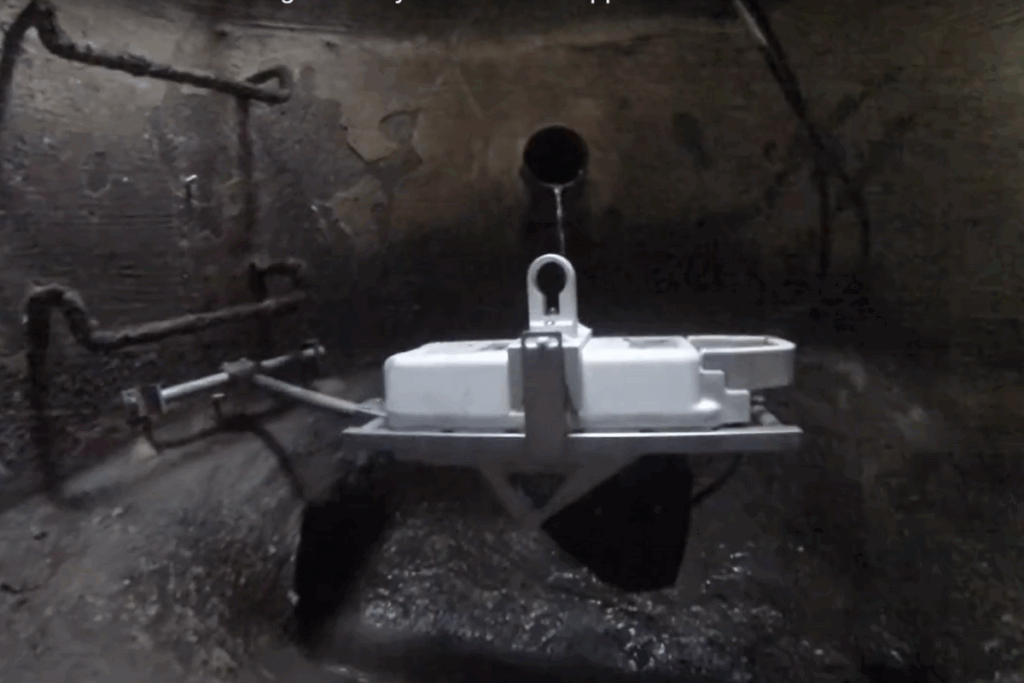

Radar technology is known for being extremely accurate, even in challenging flow conditions such as wet weather events with turbulent environmental conditions like rain, fog, dust, etc. Radar flow meters have a long-range capability making them good for large-scale flow projects, and benefit applications such as rivers, wastewater pipelines, and canals. These non-invasive meters are easy to install and maintain, as there is no contact with the fluid being measured, leading to a long product lifespan.

An installation photo of the FLO-DAR Area Velocity Sensor, a Hach Flow Solution by McCrometer, which utilizes radar technology. Photo permission by Oratech Controls, Inc.

Laser technology is highly accurate, measuring fast flows with precision. Requiring no contact with the fluid being measured, laser technology means that meters are easily installed and maintained, as there is no flow wear and tear with a non-contact device. In applications where highly accurate measurements over short distances are needed, laser technology fits the bill.

Technology Limitations

Radar technology is known for its accuracy, but in certain cases foam, vapor, or turbulence on the water surface may affect readings due to signal interference. Additionally, slow velocities may be harder to read, producing an inaccurate measurement. Radar and laser meters tend to be more expensive than submerged ultrasonic flow sensors, which may be taken into consideration if users aren’t utilizing radar meters for large-scale projects. Submerged area velocity sensors are generally more accurate than non-contact sensors, but assuring their accuracy requires significantly more ongoing maintenance. In many applications, non-contact sensors can be calibrated to yield comparable accuracies with much longer service intervals.

Laser flow meters, while touted for their accuracy, are often more affected by environmental conditions that interfere with the laser such as rain, fog, foam floating on the water surface, or condensation on the laser’s optical window. High particulate flows, common in wastewater and storm water applications, may also affect the integrity of readings, as may high levels of entrained air (bubbles) – common at higher velocities – may scatter the laser light. Laser flow meters can also be affected by vibrations, air turbulence, and temperature fluctuations as well.

Combining Technologies for Better Monitoring

Flow measurement solutions on the market will often supplement radar or laser technology with a secondary or additional technology such as Doppler ultrasonic or electromagnetic. While laser or radar provide regular readings, an additional electromagnetic or Doppler ultrasonic sensor may provide conditional flow measurement in the event of a surcharge when flow levels rise to meet or submerge the sensor. When operating in conjunction with a secondary technology, radar and laser flow meters ensure a more continuous, accurate reading of the flow in various conditions.

Selecting the Best Technology for Your Flow Project

There is no “one size fits all” solution when it comes to flow measurement. Each project must take into consideration the flow conditions, the installation environment, and objectives for measurement when selecting the right fit flow meter. In addition to reading case studies, specification sheets, and other technical documentation for each flow technology and meter, it’s recommended to speak directly to the meter manufacturer or representative to receive an evaluation or assessment of your flow project for a more custom fit.

Related Posts

Request More Information