The UltraLiner™: McCrometer’s Fusion-Bonded Flow Meter Liner

Electromagnetic (mag) technology is highly accurate, is offered in a full bore and insertion style, and is a well-known option for metering. Mag meter technology offers significant convenience and value-added features for municipal, industrial, and even agriculture customers.

Mag meters often bear an ‘Achilles’ heel’ in its design, known as a liner. Liners, frequently featured in the full-bore style of mag meter, protect the meter body from the flow media. In municipal applications, liners may also contribute to a meter’s compliance with drinking water regulations. However, numerous mag meter liners are prone to problems such as tearing, delamination or separation from the meter body, and perforation from flow debris such as rocks or even harsh chemicals causing corrosion.

McCrometer’s solution to this common flow problem? A proprietary fusion-bonded epoxy, the revolutionary UltraLiner™.

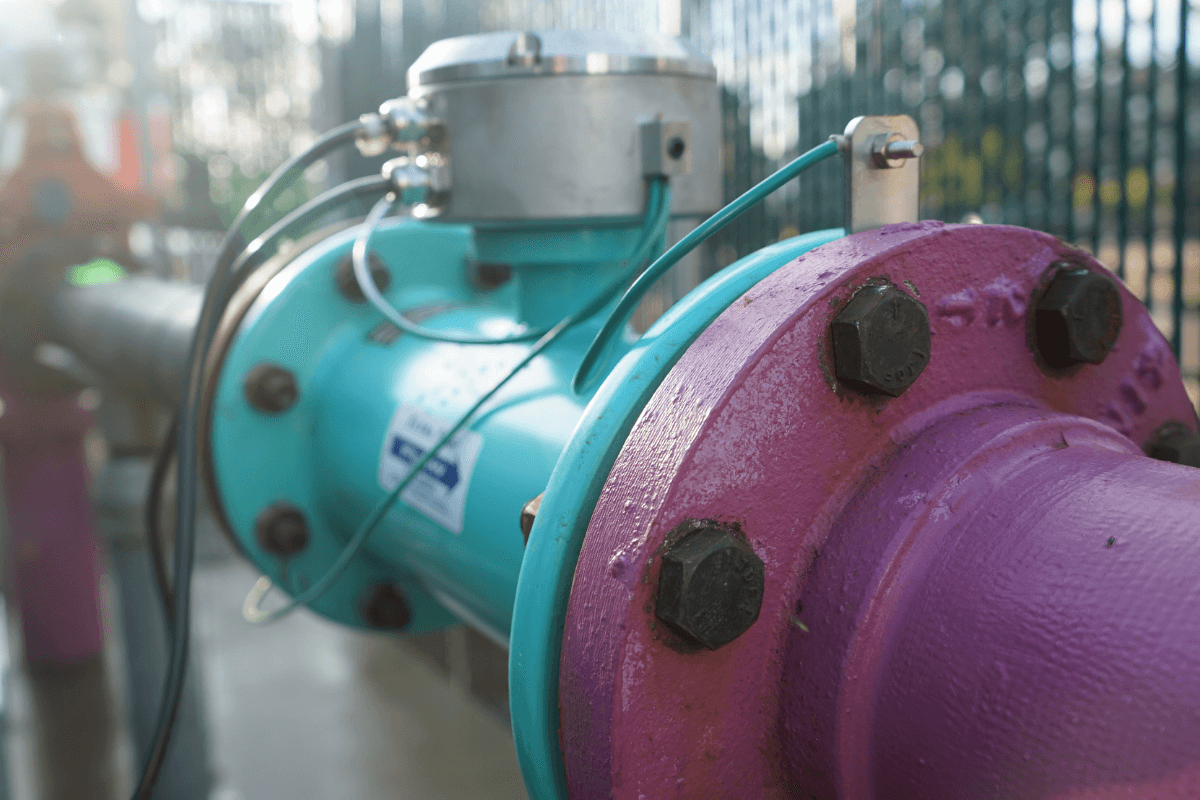

An Ultra Mag installed in a municipal well application.

UltraLiner Technology

Faulty liners can generate serious issues for operators, engineers, and irrigators. A delaminated liner can lead to blockages, get sucked up by a water pump, or caught in a valve causing expensive downtime and maintenance.

Tearing or perforation can cause a flow meter that once was NSF-61 and NSF-372 certified to no longer provide the same standard of performance and protection, possibly inducing environmental or performance issues.

These pain points across many industries and flow applications are what led to the creation of the proprietary fusion-bonded epoxy coating. When this coating lines a McCrometer mag meter, effectively eliminating the need for a traditional lining, it is trademarked the UltraLiner. The epoxy coating is comprised of materials engineered by 3M, a trusted manufacturer, and applied to many of the mag meters produced in McCrometer’s factory headquarters in Hemet, CA by certified personnel.

The UltraLiner is an effective, field-proven mag meter lining that offers a lifetime guarantee against delamination and tearing.

Field-Proven Performance

McCrometer’s mag meters with the UltraLiner have been installed in a variety of flow applications where performance is crucial. In agriculture, the Dura Mag™ and the Mc®Mag3000 have been implemented to measure harsh flow media for applications such as chemigation and fertigation, as well as dairy effluent, all of which require resistance to corrosion.

In the municipal industry, many customers who have made the switch to McCrometer meters such as the FPI Mag® and the Ultra Mag® have done so due to past experiences with liners delaminating and damaging a nearby pump or causing a blockage. Both issues can be costly to remedy, especially if the metering location is buried in a vault or the blockage isn’t easily accessible. The signal that mag meters produce can go haywire and users will receive inaccurate readings, interfering with decision-making and daily operations. The FPI Mag’s hot-tap installation, retrofit capability, and durability provided by the epoxy coating are factors contributing to its popularity in municipal and industrial settings.

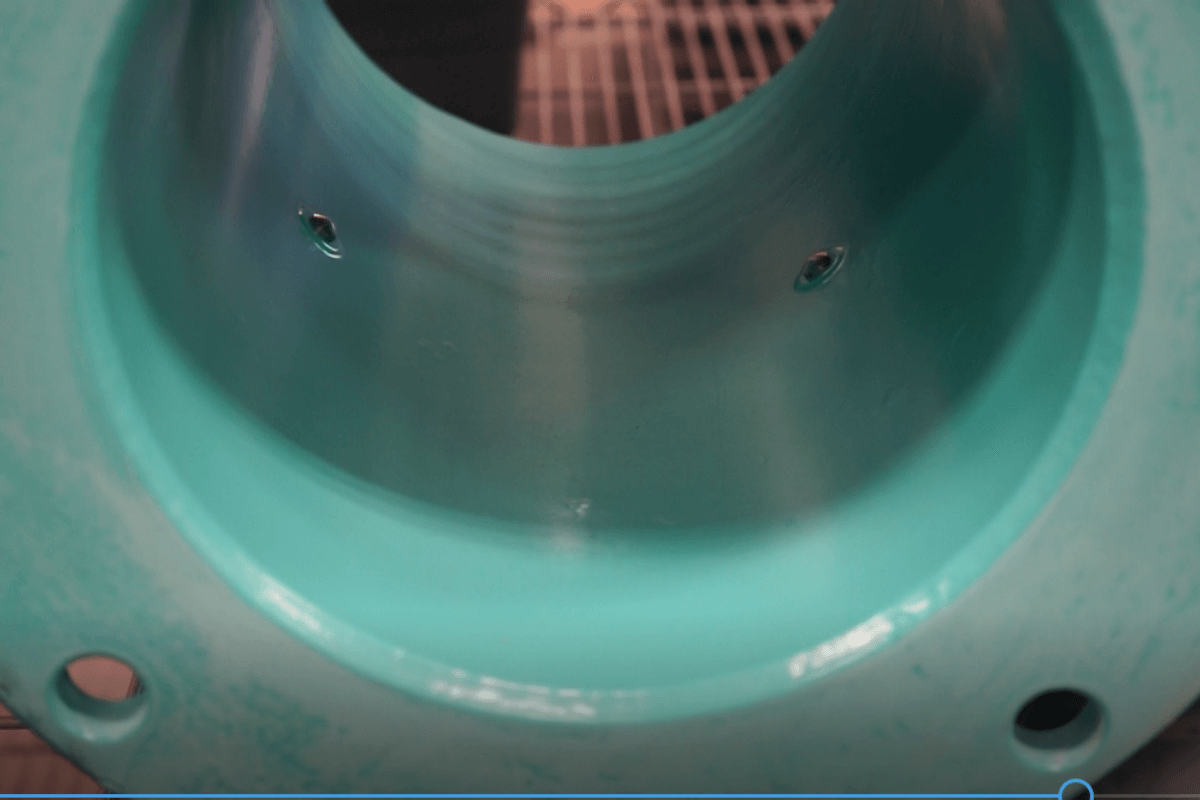

The inside of a Dura Mag, showing the UltraLiner and electrodes.

In industrial applications, shutting down an operation produces massive inefficiencies and expenses, and possibly regulatory issues if a liner tears in a food and beverage factory. For segments such as pulp and paper or automotive, harsh chemicals can corrode flow meters if the liner cannot maintain its integrity. Engineers and operators have chosen McCrometer’s mag product line to prevent such occurrences and enjoy the peace of mind that comes with implementing a mag meter with a lifetime liner guarantee. A mag meter with a 20+ year life span, minimal maintenance, and guarantee against liner issues is a worthy investment.

The UltraLiner Process

McCrometer’s factory process for manufacturing the UltraLiner is what makes the product unique and why it continually outperforms other liners on the market. To coat the flow meters with the epoxy, critical areas are masked, and the meter is blasted to remove any foreign particulates. Then, the meter is hoisted down into a fluidized bed dip tank where powdered coating is applied, bonding the epoxy onto the meter body or sensor. Post-dip, the meter is visually inspected for quality assurance, sanded down for an even coating, and then baked in an oven to finish.

The UltraLiner Epoxy

The UltraLiner is a more durable alternative to the traditional meter liner, such as rubber or plastic liners used by other meter manufacturers. McCrometer’s custom factory setup is what allows such a robust epoxy to be used. In addition to the full-bore mags, the epoxy is also featured on the sensors of the FPI Mag, the Mc®Mag 3000, as well as the propeller product line as well.

The pipe and flanges of the Water Specialties® propeller meter as well as the Mc®Propeller meter are sprayed with a coating of the epoxy to combat rust and degradation. This contributes to the long lifespan of both meters, and its uses for dirty water flows and flow media containing debris.

Is an UltraLiner Mag Right for Your Flow Project?

A great benefit of McCrometer’s full-bore mags is that the UltraLiner isn’t an upgrade feature, or an add-on. It is a standard feature and is a component of the meter that contributes to the product’s durability, reliability, and long lifespan. It also contributes to both the Dura Mag and Ultra Mag’s minimal required maintenance. For customers remedying previous liner issues or wanting to prevent liner issues in the future, the UltraLiner is a failsafe choice, backed by the lifetime guarantee.

For irrigators, engineers, and operators interested in an insertion mag or a propeller meter, the epoxy behind the Ultraliner is utilized for those meters as well, protecting the electrodes and the meter body, respectively.

To learn more about the UltraLiner and McCrometer’s fusion-bonded epoxy, as well as explore what flow meter might be the right fit for your flow project, visit www.mccrometer.com or contact the factory to speak with the experts.

Related Posts

Featured Posts

Get into the Groove: McCrometer’s Grooved-End Mag Meter

We’ll share the big news upfront! McCrometer’s integrated grooved-end mag meter is the only version on the market, and it’s revolutionary for a reason. Engineered to meet customer demand, this meter launched in January 2024 and is available for order now. This...

Produced Water and Blending Flow Meter Use Case

Produced Water is a byproduct of oil production. Whether it is a byproduct of flow back or the water component of the oil separation process, produced water can be a difficult measurement point but is a very important part of the process. Several parameters make it...

Get your Groove on Now: McCrometer’s Grooved-End Mag Meter Now Available

It is time to get your Groove On. McCrometer has released their innovative Electromagnetic Flow Meter with integrated Grooved End connections. Are you tired of bolting on extra flanges with Victaulic end connections welded to them? It is time consuming and makes an...

Request More Information